What fume hoods exist, selection rules

For research, analysis and experiments with toxic substances, a fume hood is used, which is often used in industrial production, scientific laboratories and educational institutions. The use of toxic, explosive chemicals can be dangerous for personnel or equipment, and a high-quality exhaust system will ensure safety and an excellent result.

Features and specifications

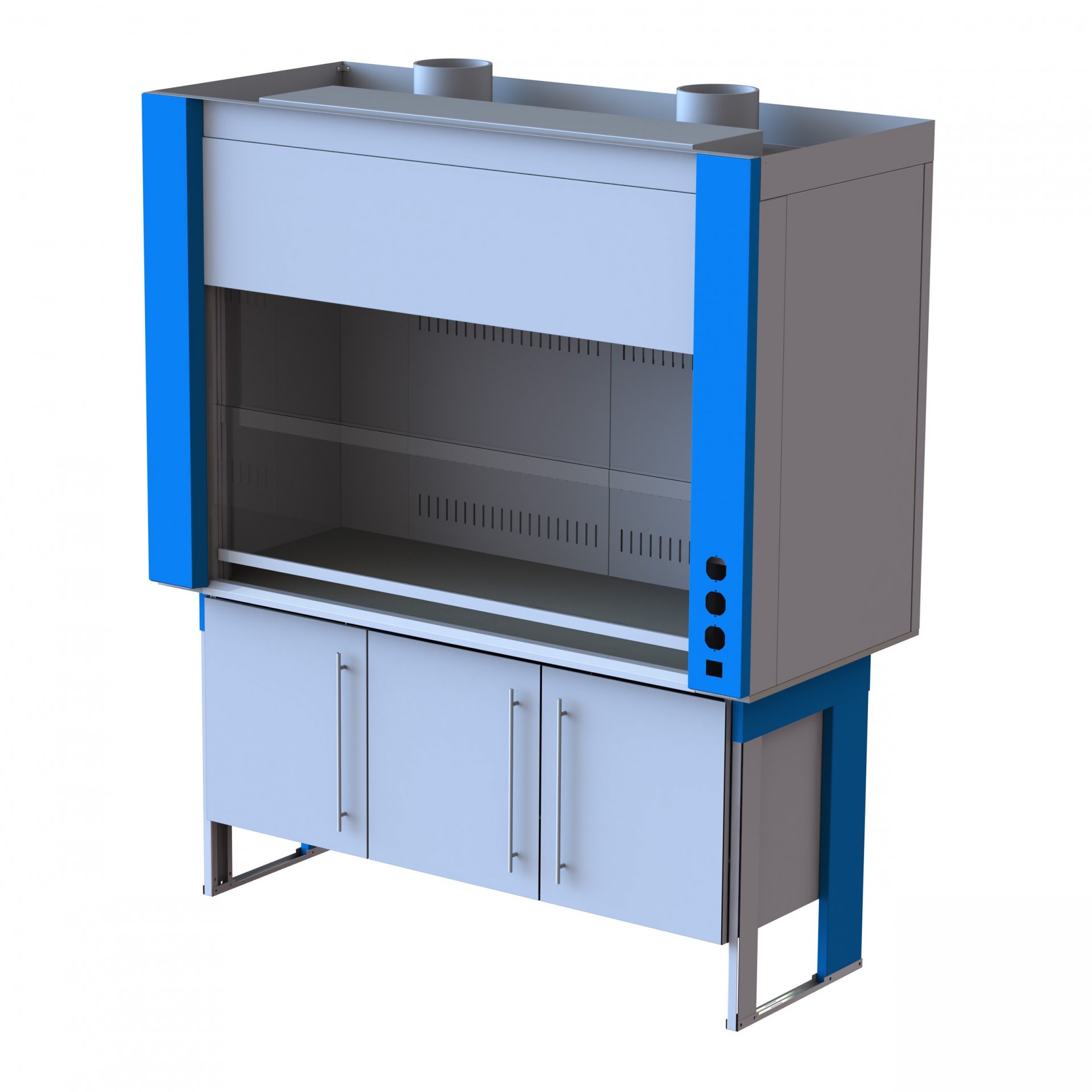

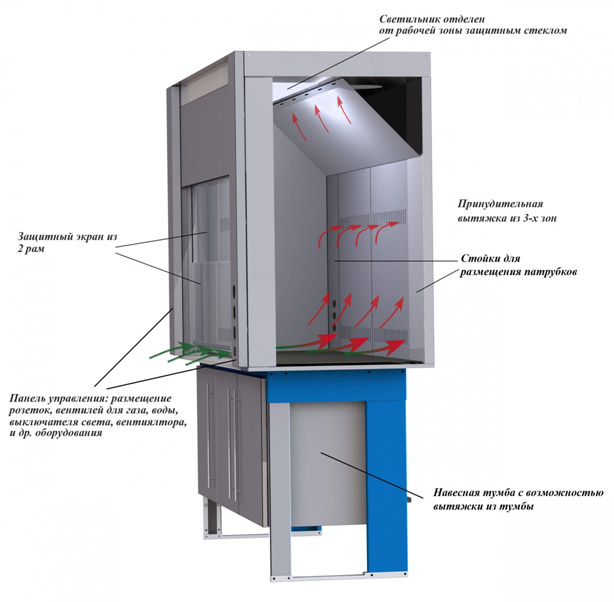

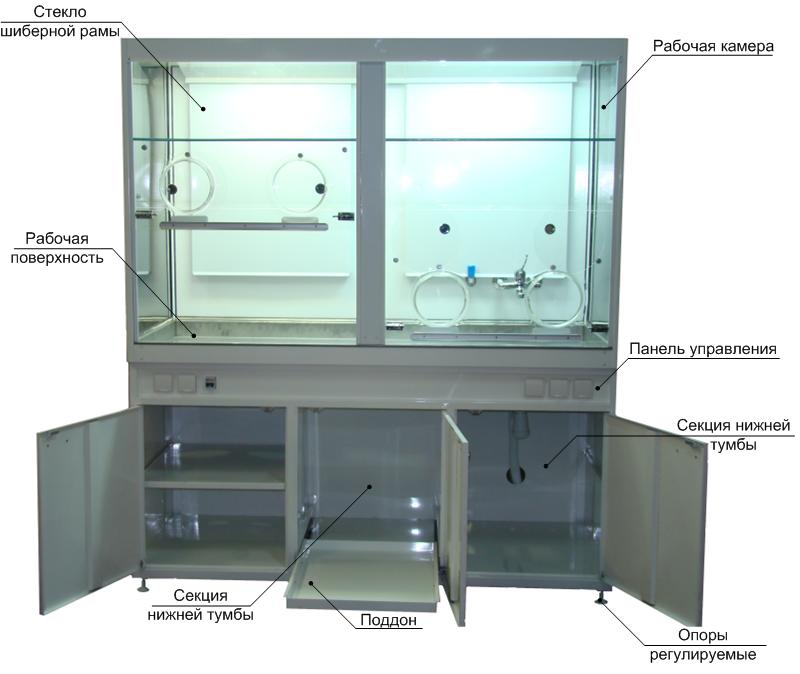

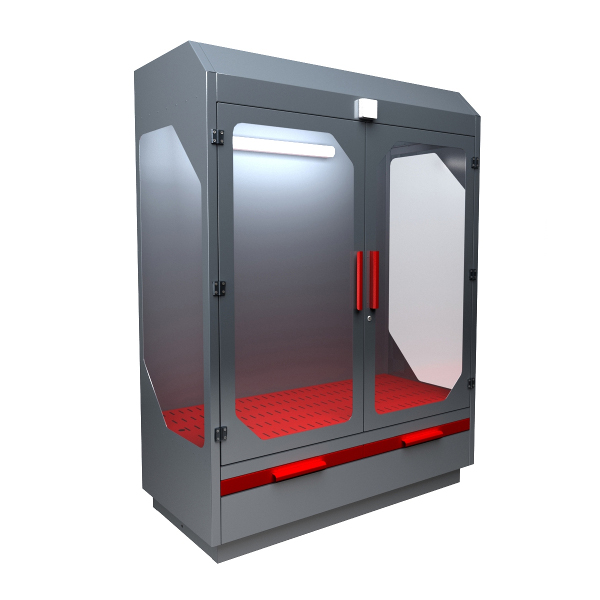

Laboratory fume hood is a solid frame construction made of chemically resistant materials. The main elements of the cabinet are the working chamber, frame, exhaust hood. Additionally, they can be supplied with a supply of water, compressed air, a vacuum pump, heating panels, protective screens, as well as convenient hanging cabinets for storing various things.

The size of the equipment can be different and is determined based on the needs of the enterprise. The working plane is characterized by increased strength, each part is easily cleaned and disinfected with chemical solutions. For processes using flammable and explosive substances, special designs are used that are protected from explosion, there can be 1 or more. Such models are extremely robust and ensure personnel safety.

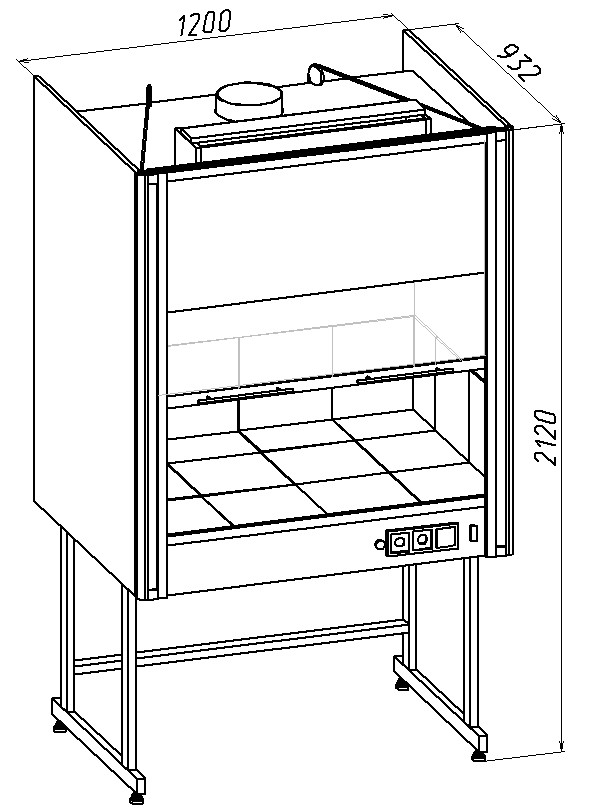

Demonstration hood is characterized in that its side and rear panels are made of transparent plexiglass. Often purchased for schools in the chemistry room, as well as secondary special and higher educational institutions.

A fume hood for a laboratory may have the following technical characteristics:

- different area of the working plane;

- the presence or absence of a sink;

- different hood power;

- water or gas supply;

- adjustable air flow;

- the presence or absence of a vacuum pump;

- level of resistance to high or low temperatures, chemical influences, possible impacts, and other damages.

Varieties

The most popular model is a fume hood and sink designed for washing laboratory glassware and equipment. This design is equipped with a faucet for water supply, switches, a sink with one or two bowls, protective screens with a lifting mechanism, several extraction zones, lamps. Description and specifications are subject to change or extension.

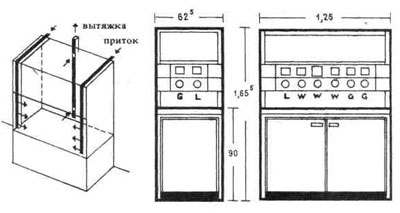

Title laboratories are in demand in industrial laboratories. In such models, protective partitions are made of high-strength tempered glass, lamps, several exhaust zones, water supply pipes, vacuum pumps, and the working surface is made of a solid ceramic plate and a stainless steel stand.

For manipulations with flammable liquids, a special fume hood is used for working with flammable liquids.Buyers should note that the symbol “J” indicates the presence of a liquid storage unit in accordance with American standards, and “D” indicates European.

Explosion-proof fixtures must be used in equipment for working with flammable liquids!

A chemical fume hood made of solid polypropylene, a high-tech material resistant to aggressive influences, is intended for the evaporation of acids. There are also special joint ventures for controlling oil products at oil refineries. A school laboratory or chemistry cabinet can also be equipped with a ventilation system appropriate to the type of work being carried out. Panoramic hood is intended for demonstration of experiments in front of an audience. For a better view, the back panel is made of glass.

Materials of manufacture

Depending on the needs of the laboratory or chemical production, the material from which the ventilation equipment is made may differ:

- stainless steel is characterized by strength and durability; it is used for muffle furnaces and other designs;

- PVC is lightweight, able to withstand temperatures up to 650C;

- fiberglass is suitable for working with acids, tolerates temperatures up to 1300С, as a rule, there are no metal elements inside;

- fume hood on an aluminum frame is used in pharmaceutical, diagnostic, environmental, and other similar laboratories.

For the manufacture of ШВ worktops:

- porcelain tiles in the form of a single piece or individual plates;

- melamine;

- plywood with a waterproof coating;

- stainless steel;

- glass;

- high strength laminate.

Given the possibilities of production, the element can be made from any of the materials listed to meet the needs of the laboratory.

Shape and size

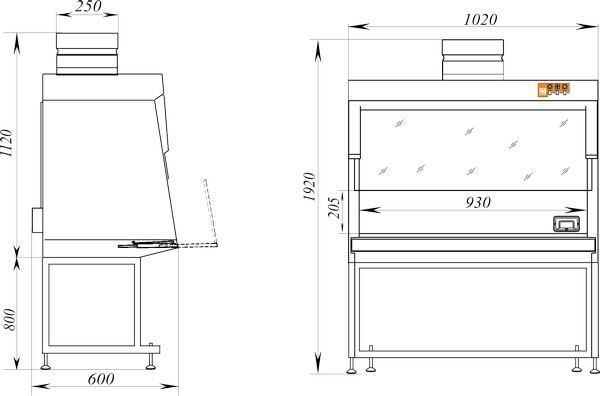

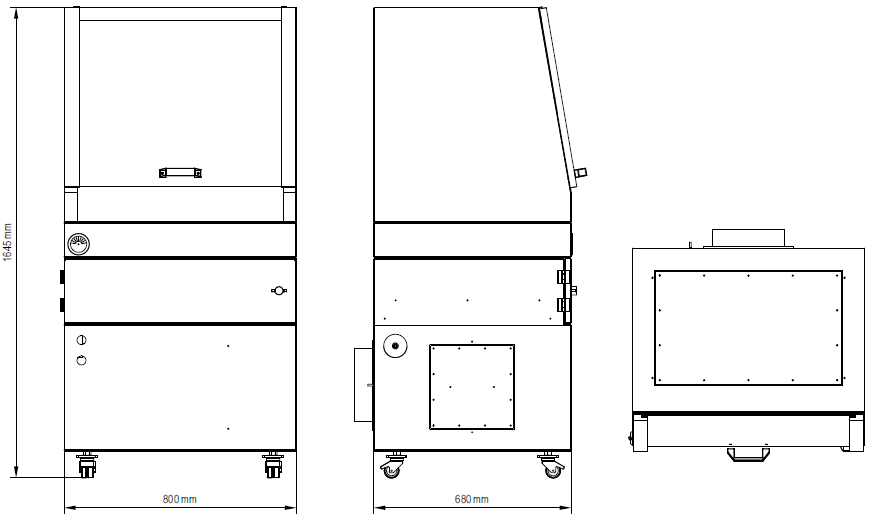

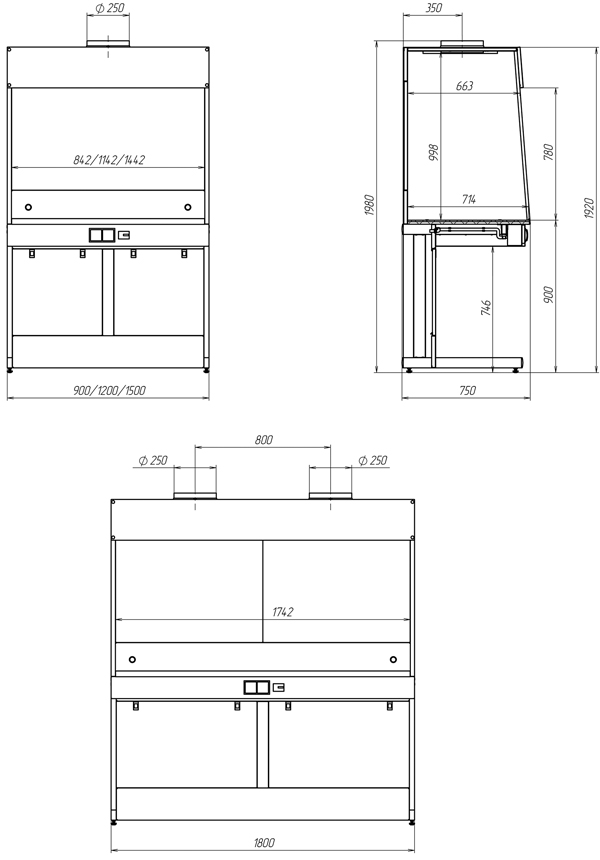

When choosing ventilation equipment, it is necessary to take into account the size of the countertop, as well as the height of the structure. Standard dimensions, as a rule, are:

| Width mm | 800, 900, 1200, 1500, 1800 |

| Depth mm | 750, 850, 950 |

| Height mm | 2200, 2400, 2600 |

The equipment should have a capacious working chamber, which will allow to freely carry out the necessary manipulations. The height of the shelves also plays a role. The work of personnel is associated with increased risk, so it is important to ensure the proper level of comfort and minimize possible threats. Another important detail is the frame opening mechanism. With a small height of ceilings it is impossible to use a cabinet with a lifting frame, a more suitable option is a sliding frame.

Most manufacturers have the ability to produce welds on individual orders, taking into account the characteristics of production. In this case, the dimensions, shape and even the design itself can be changed to better suit the needs of the customer. Design can be changed to better suit customer needs.

Video