Tips for making a highchair with your own hands, master classes

Pursuing the design of a room for a child, parents tend to purchase furniture made from natural materials. But in addition to the high cost, a limited selection of options is sometimes not satisfied. The solution will be a highchair with your own hands, which can be supplemented with a table in the same design. A variety of models, simplicity and affordability of manufacturing will help to create a real masterpiece.

Content

Necessary materials and tools

To create a baby chair with your own hands, you will need different materials that are easy to purchase in the construction department:

- boards and bars for the manufacture of seats, frames and backs;

- the self-tapping screws that will fasten the parts;

- sandpaper of medium hardness.

Of the tools for the chair you will need:

- screwdriver;

- jigsaw;

- screwdriver;

- wood hacksaw.

In home production, it is better to use natural materials. Plastic chairs significantly lose them in terms of performance and other important characteristics. Firstly, they do not have high strength. Secondly, their safety for children has not been experimentally proven. Natural wood has a high cost, but such children's furniture is environmentally friendly and absolutely safe for health. Useful properties are preserved even after complete processing. The following types are preferred:

- Pine. This is a budget option. The antiseptic properties of wood are appreciated. The finished product is easy to paint. The disadvantages include the fact that in the absence of proper care, the chair and table can swell, crack.

- Beech. Its qualities are similar to oak. It is easily restored if minor damage forms on the surface.

- Oak. Furniture for children from this array will last the longest, while it is not subject to decay, even with frequent contact with moisture. It retains an attractive appearance for a long time - even a very active child will not be able to scratch it.

MDF during operation does not emit hazardous resins. The material is strong enough, the average service life is 10 years (provided that they do not drop anything onto the surface, do not hit it). Therefore, deciding to make a highchair with your own hands, it is better to refuse MDF. Moreover, the cost of the finished product is only slightly lower than that of solid wood models.

Plywood is an environmentally friendly and safe material. Easily amenable even to very fine processing, has a low cost in comparison with natural wood against the background of a long service life. The disadvantages include a limited range of applications.

Particleboard has a low cost.The disadvantages include increased flexibility and the presence of formaldehyde resins. It is not recommended to make children's furniture from such raw materials - allergic reactions can occur to it.

Product Dimensions

When starting to make a chair for a child with his own hands, it is important to take into account the following rules:

- When sitting on furniture, the feet should be completely on the floor, legs should be bent at the knees by 90 degrees.

- The back of the stool is strictly vertical, fits snugly to the base.

- The outer edge of the seat should not put much pressure on the inside of the knee.

Children's chairs are classified by purpose. The first group includes models for feeding. Such products traditionally come with a table. Most often they have dimensions:

- stool height - from 840 to 900 mm;

- back width - 450 mm;

- the height of the stool to the seat - 500 mm, to the back - 700 mm;

- the width of the armrests is 400 mm.

The second group is a small copy of adult products. Determine the size will help the table of correspondence of the height of furniture to the growth of the child.

| The height of the child, in cm | Chair height in cm |

| Less than 85 | 180 |

| 85-100 | 220 |

| 101-115 | 260 |

| 116-130 | 300 |

| 131-145 | 340 |

| 146-160 | 380 |

| 161-175 | 420 |

| above 176 | 460 |

The parameters of the children's table must exactly correspond to the dimensions of the highchair.

The seat should be able to easily withstand the load. The optimum thickness is 60 mm. It is advisable to make connecting strips of the seat frame up to 20 cm. Legs in cross section can have dimensions of 5 x 5 cm - such parameters will provide sufficient stability. The recommended length of the backrest straps is up to 20 cm. All sizes, drawings, schemes of a highchair for do-it-yourself feeding and other models should be made as accurately as possible.

The layout of the future thick cardboard chair will help determine whether measurements are taken correctly. Another convenience is to easily make any changes to make the final product as convenient as possible.

Design selection and drawing creation

Stools for children can be of such models:

- Classic options - differ from adults in size. Structurally have the same elements.

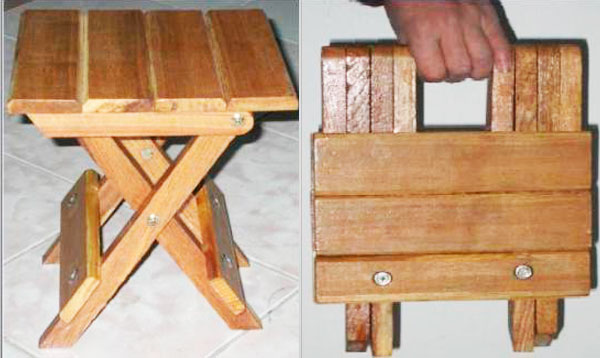

- Folding - characterized by a simple design, are actively used in small apartments, in cottages.

- Growing chairs - suggest the presence of adjustment mechanisms, which allows you to use the product longer.

- Transformers - most often represented by models supplemented by shelves for feeding and footrests. At the base there is a table that can later be used for games.

The last two models have the largest leg height. This is especially true for growing chairs that can be used from 2 to 14 years. When choosing them, it is important to carefully evaluate the quality of the structure.

A wooden stool can have a solid square, rectangular or straight through (with horizontal, vertical connecting strips) backrest. Such products support the spine well. You can also find the shape of a wide truncated cone.

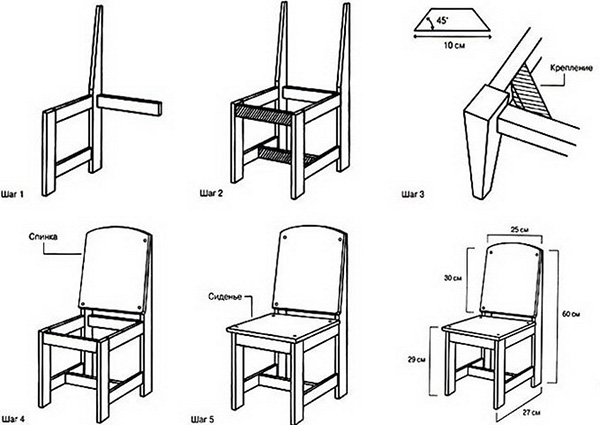

To create a sketch and drawing, you will need to take measurements and determine the purpose of the product. You can use pencil and paper, but it is much more convenient to automate the process using specialized programs. It is convenient to create “explosion schemes” in them, which will tell you how to assemble a chair.

An explosion scheme is a sketch of a product’s design with detailing, which allows you to disassemble a chair into individual elements, evaluate their number and size.

When drawing up a drawing, it is important to affix the dimensions of each part on it. For convenience, on the side, you can make callouts indicating the exact parameters of the structural elements. If you decide to use a ready-made scheme, you can adapt it to your personal needs by changing the numbers. In this case, it is necessary to strictly observe the proportions.

Design decoration

Natural wood products require protection from external factors. To solve this problem helps coating.Experts recommend choosing an acrylic version of this material. He creates a coating that is not afraid of any childish pranks - spilled water, paints.

If you want to make the product more interesting, you can color it. Bright but non-eye-catching colors should be preferred. Suitable muted light green, mint green, pomegranate, coral and others.

The materials used must not contain lead, other heavy metals, or hazardous or harmful compounds. In contact with the surface treated with these coatings, the child's health may deteriorate.

It is not recommended to decorate the table and chair with volumetric decor. First of all, due to the fact that he is one of the most common reasons for injuring a child. The best decoration will be hand or screen painting. For young children, applications and drawings of heroes of fairy tales, cartoons are suitable. Curly legs will look interesting. If the chair has a backrest, various figures are cut out on its surface with a jigsaw.

DIY manufacturing steps

There are two main models of chairs - tall and ordinary. On their basis, numerous modifications are created. Any of them can be performed independently with a minimum of tools.

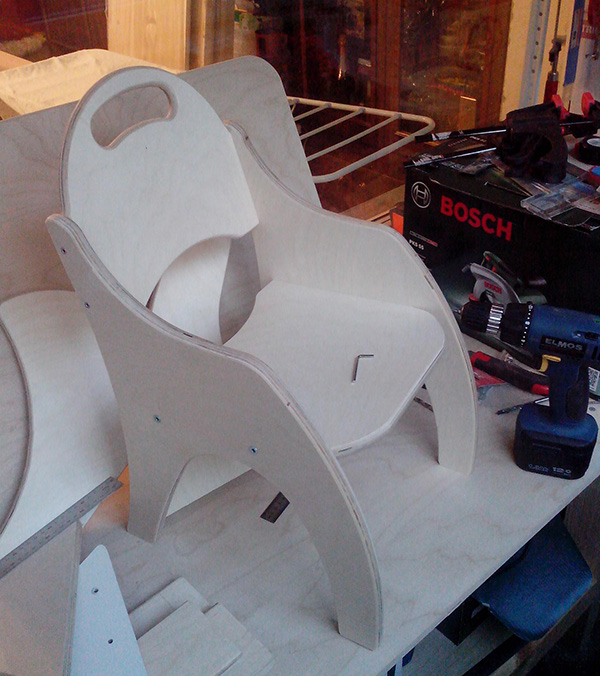

Plywood high chair and table

To make such a model, the following materials are useful:

- plywood 9 mm;

- glue for wood;

- sand paper grinding machine;

- milling cutter;

- jigsaw;

- varnish or paint;

- mortise edging.

The scheme made of plywood with a do-it-yourself table and chair includes a certain set of parts. Required Items:

- support (2 pieces) - 370 x 340 mm;

- stiffness shield - 490 x 270 mm;

- countertop - 600 x 400 mm.

You will also need blanks for a plywood baby chair:

- support (2 pieces) - 280 x 260 mm;

- seat - 280 x 210 mm;

- back - 490 × 280 mm.

The procedure includes the following steps:

- Sheets are cut to size. Electric jigsaw rounds are made at the corners of the countertops, backs and furniture supports. Due to this, a plywood stool will be safe even for a very small child.

- All places of cuts are processed with a grinder.

- The milling cutter selects the grooves into which the mortise edging is laid.

- Fastens all the details of the table and chair.

Detailed drawings and diagrams of the stool will greatly facilitate assembly. Corners can not be cut, but then you need to purchase special plugs. Finally, the piece of furniture is varnished or stained.

Transformer for feeding

The design will be stable, if guided by the drawings. To make them accurate, it is better to use special programs that will help you figure out how to assemble a highchair. Work Stages:

- Sawn the bars in size, all places of the cut are sanded with sandpaper.

- Roundings are cut out of the board using a carpentry machine.

- In the places of fixation, holes are drilled that match their dimensions with the dimensions of the dowels. The optimal depth is 30-40 mm.

- Assemble the sides of the highchair. The legs are fastened with the lower crossbar; rounding is fixed to the upper crossbar; the elements obtained are glued together.

- To make the seat and back, 6 rectangles of 300 x 250 mm are cut. The corners adjacent to the long side are rounded. Glue plates of 3 pieces. Finished parts are additionally fastened with a metal strip, with screws.

- They connect the sidewalls and the transverse trims with dowels, having previously lubricated the joints with the adhesive. In the same way, strips are attached to the structure that will support the countertop and back.

You can make a highchair with a soft seat. It will be much more comfortable for the baby.For this purpose, foam rubber with a thickness of 2 cm is glued onto the seat and back blanks, then fitted with a cloth. It is better to choose a material that is easy to wash.

The feeding table is assembled using the same technology as the chair. All surfaces after sawing must be cleaned with sandpaper. At the end of assembly, the product is allowed to dry completely, after which it is varnished or painted.

Stool in the nursery

Such products are very similar to adult models. The main difference is size. For children, the optimal height setting is 20 cm, in rare cases - 25 cm. The seat should be 250 x 250 mm in size. A classic stool does not have a back, but in case of operation by kids, an exception can be made. They give it a shape, for example, of ears or a heart.

To make a stool with your own hands, you will need a board up to 5 cm thick. The operation procedure includes several stages:

- The selected sheet of wood is treated with sandpaper No. 60 or 120 to remove serifs and chips.

- Saw the material according to size. Mark out the location of the mounts.

- Places of cuts and surfaces are treated with sandpaper or a loop machine.

- The blanks are first coated with stain and then with varnish. If desired, before this procedure, jumpers and supports are given a curved shape.

- Based on the drawing, fasten all the details with wood screws.

If you put a stool on a low table, the resulting area is convenient to use for feeding a child or playing with him. The product should stand on a flat surface, which will exclude falling. For children under 3 years old, you can make a stool up to 15 cm high.

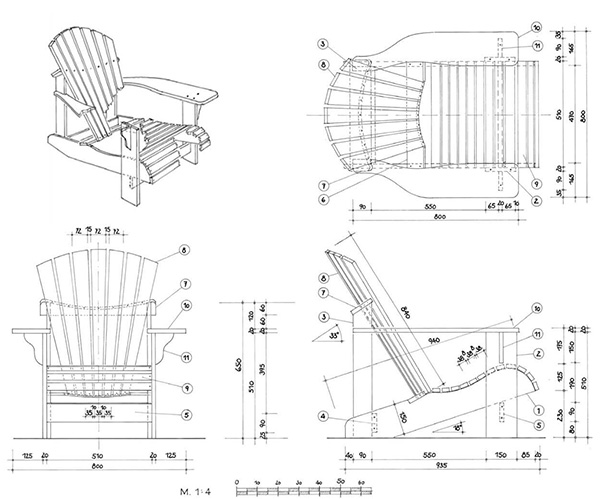

In the form of a typewriter

At the heart of this model is the Adirondack garden chair. The image, for example, Lightning McQueen, is easy to give if you draw the face of the hero. Many do not know how to make highchairs as similar as possible to a car. To do this, add the wheels from plywood and cover them with stain. To work, you need a pine board with a thickness of 20 mm. The manufacturing procedure includes the steps:

- According to the drawing, all the details of the future chair are cut out. Carefully treated with an antiseptic.

- Drilling points are outlined, the side supports are connected in turn with the front legs. Crossbeams of a back, a level of a seat are added.

- On the front legs are fixed props, which are then attached to the armrests of the stool.

- The back straps are fixed.

- The final stage is the tinting of all surfaces of the stool.

The back of the chair can be slightly lengthened. This will allow you to get an additional playing surface. It is also convenient to store books and toys in it.

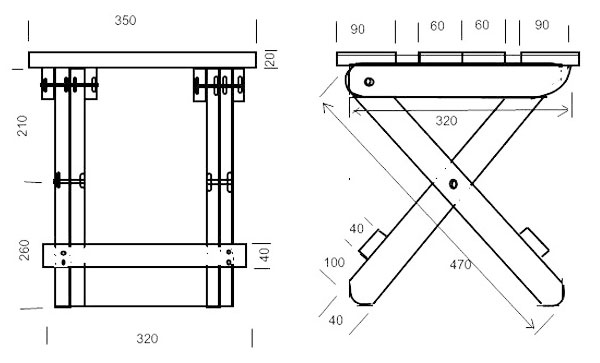

Folding chair

The request how to make a children's table with your own hands so that it can be folded is common. Models of a similar design are also popular. They fit perfectly into the small nursery.

To get a folding chair made of wood with your own hands, perform the following steps:

- All details are cut out of wood, carefully processed.

- The rails are attached to the supporting bars. This forms the seat of the chair.

- From the front legs, the backs form a frame. The rails for the back are attached to the support legs, and a crossbar is installed in the lower area.

- Both rails are attached to the rear legs of the stool.

- 2 frames are fixed by bolting.

- Connect the chair seat to the front frame. Drill through holes and fasten with bolts, which provide folding.

Children's chair - a variant of furniture, which is a must. It is easy to assemble at home, even with minimal knowledge.The quality of work is ensured by the accuracy of the drawing.

Video