How to make a do-it-yourself table from home boards, recommendations

Beautiful wooden furniture never goes out of fashion, as it is practical, functional, natural. Its main advantages are durability, strength, as well as the possibility of self-manufacturing. Before you make a table of boards with your own hands, you need to understand the types of structures used by the materials, the features of the construction of the drawing. In addition, it is important to determine the optimal size.

Content

Benefits of DIY

It is not difficult to buy a finished wooden table, but independent production has certain advantages:

- reduction in the cost of the product;

- the possibility of independent choice of working material;

- strength and durability: even an inexperienced craftsman will try to make the structure reliable.

Another person can independently choose the product design, sizes that will correspond to the parameters of the room. A table of boards can be entered into any interior, as it can be of various shapes and designs. The resulting product will become exclusive, because you can always independently develop a unique project for it.

Models of tables from boards

Before making a street table or products for the garden, home, you need to decide on its model. The most common type is a design with a frame on four legs. Even an inexperienced person can make it. There are also round products, angular, models, in which benches are connected to the main structure. Tables can be classified by purpose, design and shape.

By appointment

To make a table from boards with your own hands, you need to decide for what purposes it will be used. According to this parameter, the models can be classified as follows:

- Dining. It is large in size, not only the whole family fits at the table, but also invited guests. The presented product is not suitable for small rooms.

- Magazine. Its main function is decorative, and therefore its dimensions are small. The standard height of the structure is 0.7 m. Magazines, books, newspapers are stored on such a table. It can be equipped with wheels for ease of movement.

- Kitchen. It is intended not only for eating, but also for its preparation.The product can have different dimensions and shape - it all depends on the parameters of the room, the number of people who will use it.

- Garden. The most popular option. Usually it is installed in the cottage in the open air, on the terrace, so the requirements for choosing boards are strict. The design does not have to be complicated. Such a do-it-yourself little table for a summer residence is designed to provide the convenience of vacationers, so its decorative qualities go by the wayside.

There are also written constructions, for the manufacture of which solid wood is suitable.

By design

Product manufacturing begins with a design definition. It all depends on the size of the room, the purpose of the destination and the intensity of use of the model. The following types of construction are distinguished:

- A traditional stationary table that is commonly used indoors. Its size and shape are different. Most often installed in a specific place and no longer moves. Such wooden products are made with 1 or 4 legs.

- Table book. It represents a curbstone with the leaning-down countertops which are established on legs of a support. Its advantages are compactness and mobility, the ability to use even in small rooms. The disadvantage is the fast wear of the mounts during intensive use of the product.

- Transformer. This piece of furniture is convenient and functional, allows you to free up space in small houses. The size of the structure varies depending on the level of alignment. Unassembled product can serve as a dining table. The countertop increases by 2-3 times. Also in some models you can adjust the height. The disadvantage of such furniture is the fragility of fixtures and fittings.

- Hinged. It is a small countertop attached to the wall. When folded, the furniture is in an upright position and does not take up space. When unfolded, the structure turns into a table that rests on one leg. Its advantages: compactness, space saving, simple manufacturing and installation process, a variety of shapes. The fasteners are heavily loaded, so they will not last very long.

- Retractable. This copy fits well in any room, regardless of its size and design. If a table will be used by several people, then it is not necessary to lay it out. The additional design is hidden inside the model. The sliding mechanism is simple, so any person can handle it.

- Connected to benches. Most often made at the cottage. The product is a combined version - a table and benches attached to it. Typically, the model is collapsible, so in winter it can be hidden in the room. It is lightweight, is mobile. There are do-it-yourself tables for summer cottages, which when folded turn into full-fledged benches for relaxation.

Making tables with your own hands is a fascinating activity. But if the master has not worked with boards yet, then he is better off choosing a simple option: folding or traditional model.

In shape

To make a country table with your own hands, you need to pay attention to its shape. It all depends on the taste of the owner. Garden tables are rectangular, oval, round and square. For the veranda or terrace, the corner option is suitable. To make a street table for a beginner, it is better to choose a rectangular or square model. Oval or round products are more complex, so for the first time they should not be taken.

How to determine the optimal size

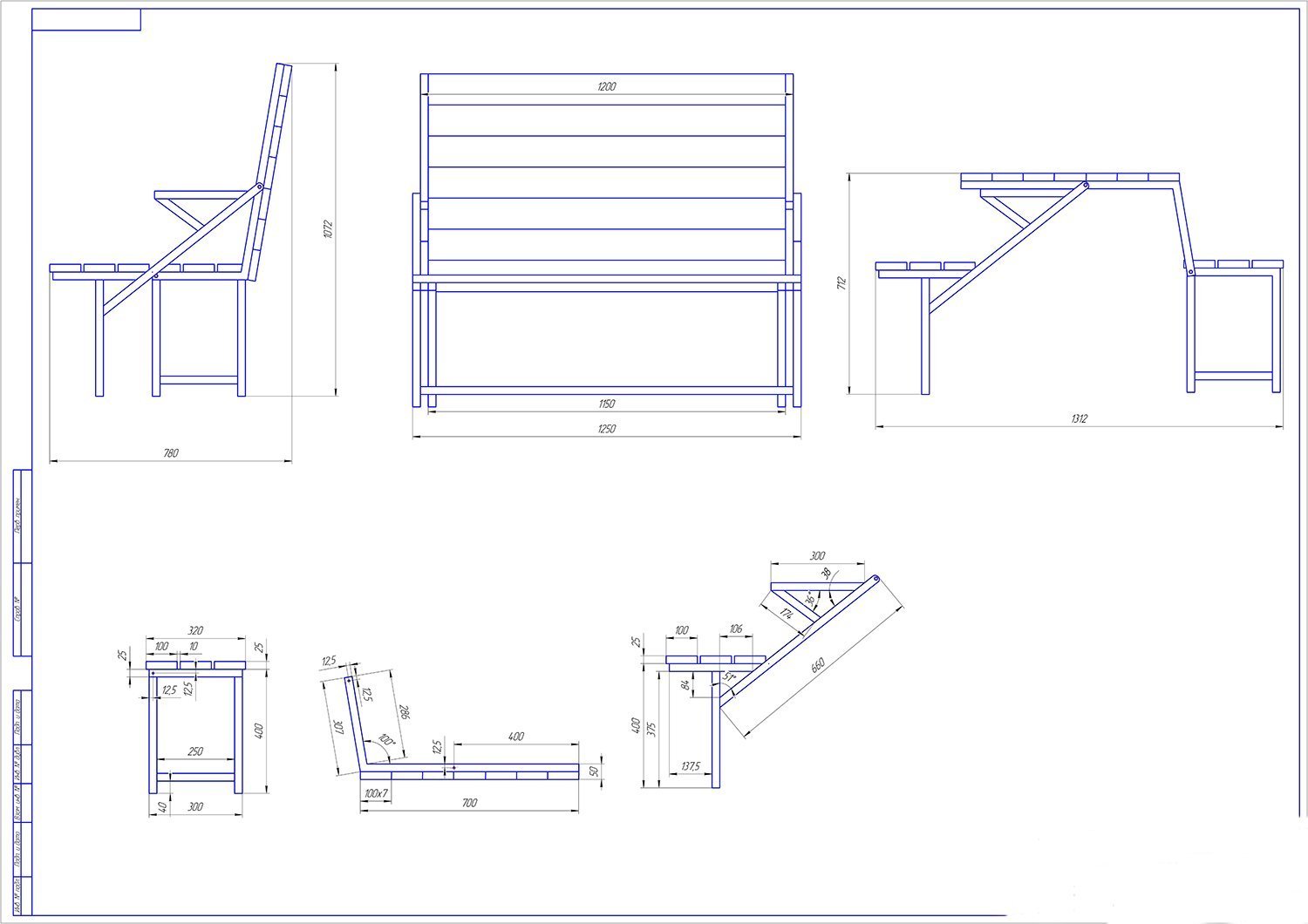

Do-it-yourself garden table construction is carried out in accordance with the drawings, the creation of which requires the dimensions of the future product. One seat requires 60 cm of width and 40 cm of depth of space.If people sit opposite each other, then the optimal distance between them is 25 cm.

The usual width of the product is 1-1.25 m. The dimensions of the square tables are 90 x 90 cm. Depending on the number of seats, rectangular and round products have different dimensions.

Number of seats (rectangular table) | Size cm |

2 | 60 x 90 |

4 | 120 x 90 |

6 | 200 x 90 |

8 | 260 x 90 |

10 | 320 x 90 |

12 | 320 x 125 |

Seats (round table) | Diameter cm |

2 | 70 |

4 | 90 |

6 | 140 |

8 | 150 |

10 | 180 |

12 | 230 |

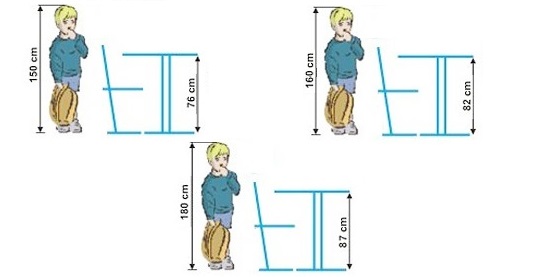

The optimum diameter of the round table is 135 cm. Larger models are used for the street. As for the height of the structure, it all depends on the height of the person.

There should be enough space around the table. If this item is placed indoors, then 1 m of free space is left around it.

Height, cm | Height cm |

150 | 75-76 |

150-160 | 80-82 |

160-180 | 87-90 |

More than 180 | 100 |

Wood selection

Depending on whether the outdoor table will be made for giving or for placement in the house, it is necessary to choose the right material for manufacturing. Recommended Options:

- Oak. Tables and benches made of this material are strong, wear-resistant, durable. They have a beautiful texture. Wood does not warp and does not deform, does not lend itself to decay and damage by insects. The material is easy to grind and drill, but it pricks poorly. The biggest drawback is its high cost.

- Beech. The product is solid, but at the same time easy to operate. The lack of material is a tendency to rot, so it must be further treated with antiseptics. It is also more deformed than oak.

- Birch. It has good strength, does not crack, does not deform. It can rot with prolonged exposure to moisture, but this problem can be eliminated with antiseptic impregnations.

- Alder. It has a beautiful color, quite soft and easy to process. A table for a summer house of this type of wood is better not to do, since it is not resistant to mechanical damage.

- Spruce. It has an even structure, but a large number of knots. It is better not to take it for the assembly of furniture used in the garden. In addition, spruce is difficult to process.

- Pine. You can make a table for your own home from such wood. It is durable, resistant to significant deformations. When exposed to moisture, the material quickly rots, but after treatment with an antiseptic, this problem disappears. This wood also has a beautiful texture and a pleasant smell.

Soft rocks are not suitable for products that will succumb to intense load or used outdoors. The base of the structure can be made of wood (walnut, oak, birch, ash, beech) or metal. It is better for beginners to start work with soft breeds: alder, pine.

Tools and consumables

For the manufacture of a table and benches for giving with your own hands at all stages of the work requires a variety of tools. Some of them are not in every house, so it is recommended to rent them. Also, tools can be purchased as needed, otherwise the total cost can be very high.

Stage | Accessories |

Markup | Ruler and square metal; roulette; building level. |

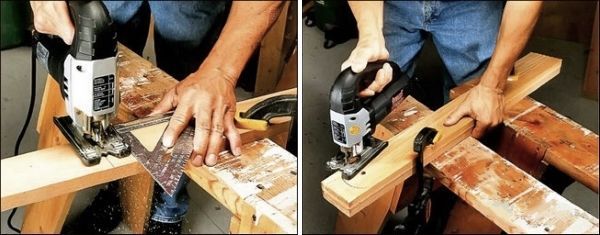

Material preparation | Saw or hacksaw for wood, electric jigsaw, jointer; Sander; sandpaper with grains of different sizes; milling machine (if necessary). |

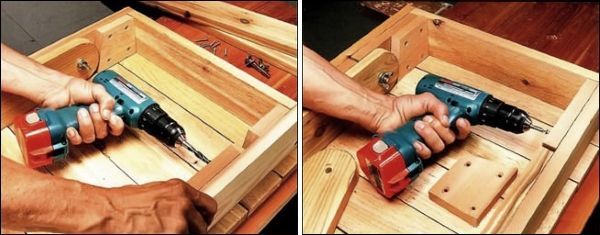

Assembly | Mallet; screwdrivers of various sizes; drill and screwdriver; hammer. |

For fixing wood elements, screws, nails or self-tapping screws can be used. In the manufacture of transforming models, appropriate accessories are required.

Drawing preparation

To build a table for a summer residence with your own hands, you need diagrams and drawings, in which the sequence of work will be indicated. To make them, you need a sketch, a pencil and a ruler, paper. When creating a drawing, the dimensions of the room, the dimensions and design of the table, the thickness of the wood, the placement of fasteners and accessories are taken into account. It is much easier to find ready-made options in specialized publications (magazines, books), on forums, but they will also have to be finalized.

You can draw or adapt a ready-made drawing using design programs. Their disadvantage is that people who are not familiar with them can get confused and make mistakes. It’s especially hard for people aged to work with such programs. Another important stage in the manufacture of the circuit is its detailing. It is made in the form of a table, which indicates the number of elements with exact dimensions in millimeters.

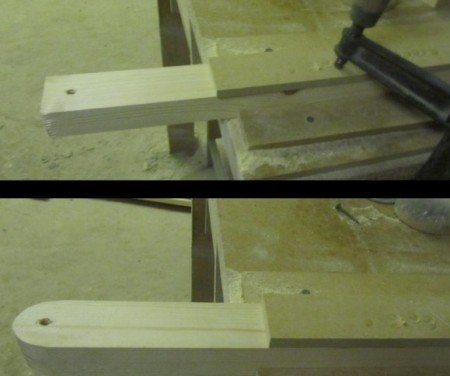

Preliminary processing

To make a table for a summer house, boards are taken with your own hands. First they need to be cut to the size indicated in the drawing. Cutting should be done with a machining allowance. To obtain the exact size of the fragment, the product must be planed. After that, grinding is performed. Particularly important is the sanding step.

If the structure will be installed in the cottage in the open air, then you need to take care of its protection from the negative effects of external factors and insects. To do this, there are antiseptic impregnations with fungicides and water-repellent effect. They are applied in several layers, after which the surface is resurfaced. Measurements, processing should be done very carefully so as not to be disappointed in the manufactured thing.

Step-by-step manufacturing

A table made with one's own hands is the pride of the owner, so you need to follow all the production technology. If the model has already been selected, the scheme and the sequence of work are defined, you can proceed with the manufacture of the structure. Each of them has its own characteristics.

Country model with benches

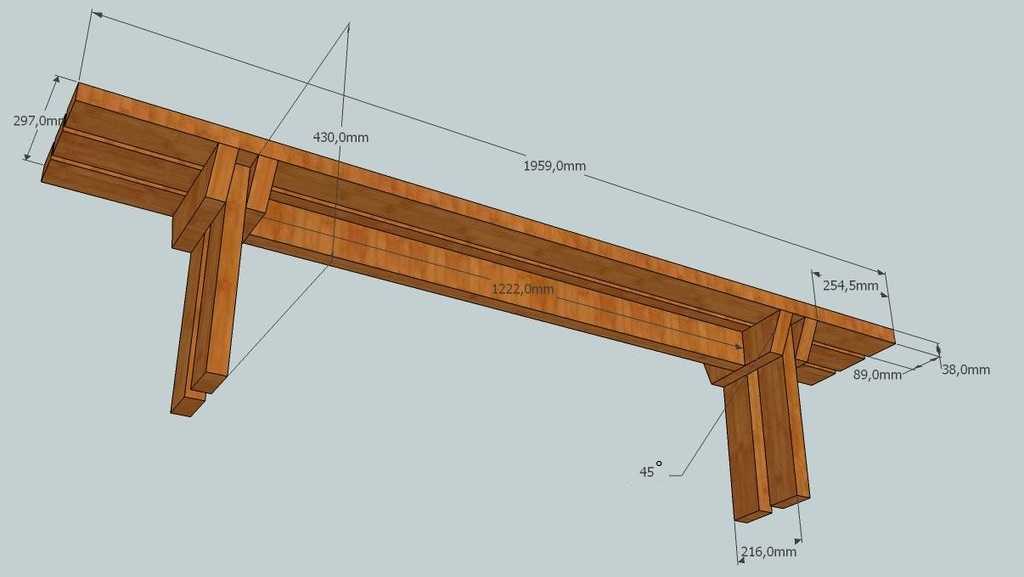

First you need to make garden benches. For one element, the following is required: 3 boards 196 cm long, 4 crossbars 30 cm each with edges sawn at an angle, a long longitudinal bar 122 cm long, 4 legs 43 cm high. The procedure for making a bench with your own hands is as follows:

- At a distance of 25.5 cm from the edges of the boards with the help of screws or nails, the cross members are fixed.

- The long longitudinal element is connected to the remaining cross members and screwed to the seat so that there is room for legs.

- The support posts are fixed last to the crossbars using self-tapping screws or nails.

Seat boards should not be clogged close to each other. The second shop is made in the same way. It is connected to the first with the help of 4 boards of 160 cm each.

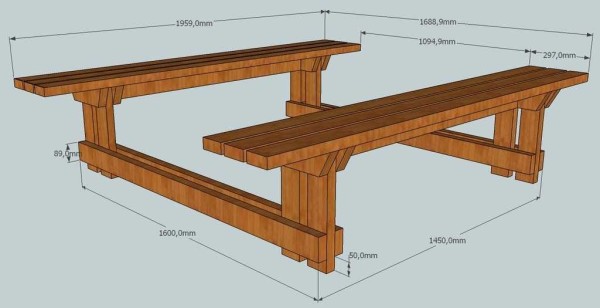

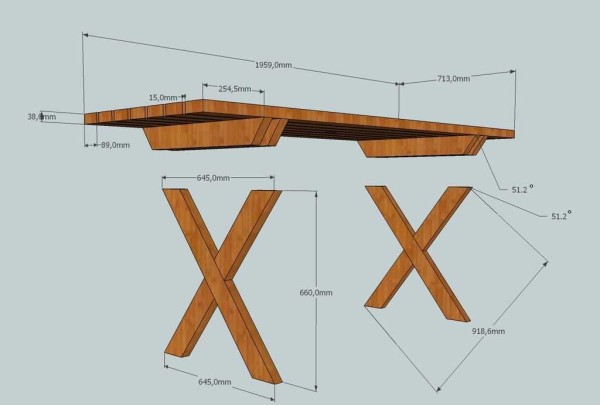

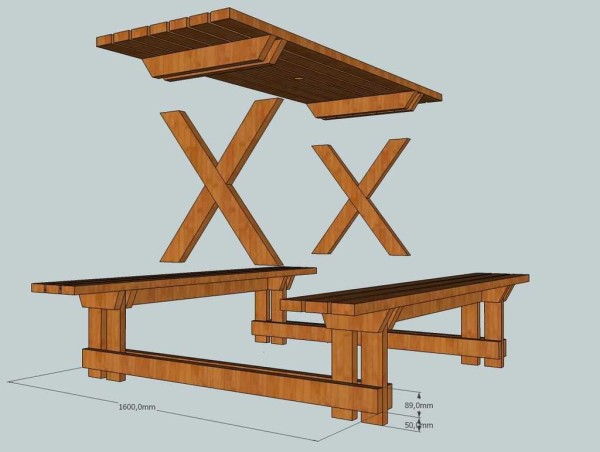

To make a garden table with your own hands, you need 7 boards, the length of which is 195 cm, and the width is 8.9 cm, 4 crossbars, the edges of which are cut at an angle of 52 degrees, 4 bars for legs. Build process:

- Countertop boards are connected by cross members in a single block.

- Next, legs-crosses are made. In the place of their intersection on one board, you need to remove the wood on half of the board and connect with the second fragment.

- Further, both crosses are screwed to the countertop and cross-members.

The last stage is painting. This design can be disassembled and stored in the utility room in the winter. If the table is in the gazebo, then it can be fixed to the benches stronger.

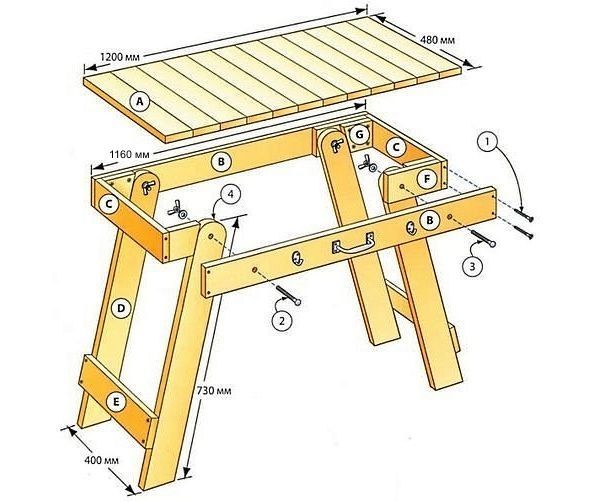

Folding product for the garden

Making a table for a summer residence with your own hands is carried out from racks. Their thickness is 1-1.5 cm, length - 140 cm, width - 10 cm. In total, 7 elements are required. We also need bars for legs (4 pieces of 70 cm), crossbars of 45 cm (2 pcs.), Crossbars for securing the supports - 4 pieces of 50 cm. Nails, nuts, bolts and washers are also used for manufacturing.

The work is performed in the following sequence:

- The legs are connected by cross members at a distance of 25 cm. Self-tapping screws are used for this.

- Reiki are fixed by the back to the crossbars.

- From the legs, frames are made crosswise with bolts.

To make the table strong and stable, the supports must be made beveled below and above.So that the boards are fastened securely, the countertop can be covered with a metal edging.

Transformer

Many masters are interested in how to make a transforming table, which, when folded, represents a rest bench. For work, you need bars and boards. Production involves the following steps:

- Cut 8 equal bars 70 cm long. On the upper and lower parts of the elements, cut at an angle of 10 degrees.

- To make frames from boards: 4 fragments 40 cm long and the same number of bars of 170 cm each are required. Next, make a cut on all the details so that 2 rectangles can be made of them, which are fastened with screws or nails.

- Create reinforcing elements to form the seat. The beam needs to be nailed at a distance of 50 cm from each other.

- Attach the legs: 12 cm from the corners to fix to the seat with the bolts that pass through the beam and support.

- Make a rectangle measuring 70 x 170 cm.

- Form a holistic design. To do this, cut 2 beams of 50 cm, which are placed between the large shield and the bench. They must be fixed on the side of the bench and at the bottom of the shield.

Lastly, cut 2 bars 110 cm long. They need to be fixed on the second bench in the center. The final stage is covering the structure with a board.

From old boards

You can make a table with your own hands made of wood, even if the material is old. It just needs to be sanded and processed well. For the manufacture of the structure requires a frame, countertop, legs. The cross-section of the bar for racks is 1.5 x 5 cm. The boards for the frame are 2.5 cm thick and 5 cm wide.

Work begins with the manufacture of the frame. Then legs are screwed to its inner corners. Last of all, worktop elements are attached to the frame. It can be strengthened with metal corners.

From pallets

To make such a table with your own hands, drawings need to be drawn indicating the exact dimensions of the future design. The pallets must first be taken apart. From the boards obtained, a countertop is formed. The table frame is made from the sides of the pallet. Using the cross members, the upper part is connected into a single structure.

Now the table frame is made. It is fixed to the countertop in the butt end with self-tapping screws. After that, legs are attached to the upper part of the structure. For the stability of the product, the supports are connected by jumpers. After that, grinding and finishing of the table are made.

Finishing and decorating

After assembly, the entire structure is ground and polished. If chips are present on the boards, they must be putty. To improve the appearance of the product and its additional protection, the wood can be varnished or painted. Before application, the surface is cleaned of dirt and dust. The varnish should dry at room temperature. Before applying the paint, the product is covered with a primer. The composition is best chosen on a water basis.

You can decorate the structure with a metal rim - this method is suitable for heavy tables. The creative staining method is also used. This requires masking tape or stencils. An interesting option is decoupage. Pictures cut from napkins or magazines are glued with PVA glue. After drying, the table is coated with colorless varnish several times.

Wood in combination with epoxy resin, which is poured into crevices, looks interesting. As long as the substance remains in the liquid phase, flowers, leaves, shells can be placed in it. It is not difficult to make a table yourself, you just need to clearly draw a diagram and observe the manufacturing technology.