Overview of furniture conductors and patterns, the nuances of choice

To speed up the manufacturing process of furniture using special devices. Even novice masters will be able to take advantage of them, in addition, furniture conductors and patterns can be made independently. Products come in different types, designed for different types of work.

Appointment

Such devices greatly facilitate the work, because with their help you can drill precise holes. Furniture conductors and patterns are necessary when assembling cabinets, tables, other interior items for the home, office, production, even furniture elements of confectioners for the bakery. During their assembly, the masters do the same actions related to marking, drilling. Special equipment will help speed up these processes.

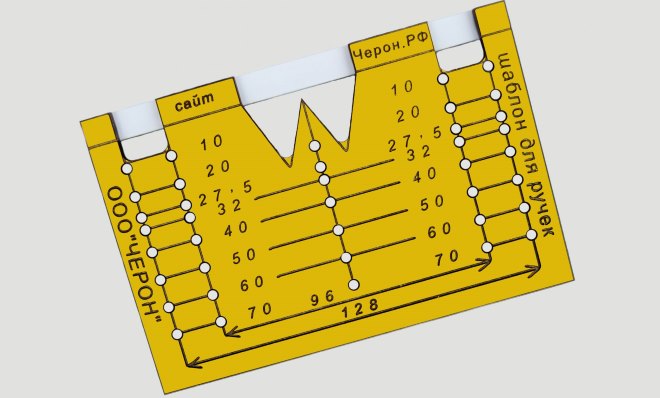

The furniture template is a bar with holes, sleeves. Between them, the distance is different, the diameter of the holes is different. Putting the jig to the part, drill holes of the right size with a certain step.

Benefits of using patterns for making furniture:

- fast drilling;

- easy hole making process;

- drilling accuracy.

Some products facilitate the drilling and assembly of parts, while others are necessary to simplify the marking. Depending on this, conductors are marking or drilling. Most often, equipment is purchased in the store, but some make the fixtures with their own hands. It is easy to make a conductor from a joiner's square or a metal ruler.

In the assembly of furniture, various products are used: rack, sheet. Rack templates are used when marking elements longer than 1 m. Sheet templates are suitable for small parts. There are also combined devices that combine several types.

Device and specifications

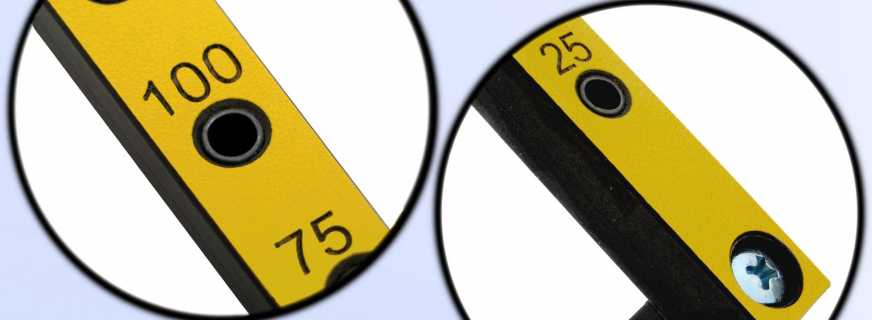

The conductor is made of wood, metal, plastic, MDF, chipboard and other materials. There are standards according to which holes are made at a distance of more than 8 mm, counting from the edge. The distance between them is not less than 32 mm. The centers further expand, install the thread, and put the emphasis on the rail.

An important element of the conductors are their supports, which are necessary for the firm fixation of the fixture on the furniture part. Supports are spherical, notched, flat. To install the bushings, the following types of plates are used:

- outboard;

- lifting;

- rotatable;

- Permanent

- removable.

Varieties

Furniture pattern can be of different types. Products differ in design method, functional features. Depending on this, conductors and patterns for marking and drilling can belong to one of the categories:

- waybills;

- rotary;

- overturned;

- universal.

Overheads are considered the best option for drilling holes in flat parts. They are suitable for boards made of chipboard, MDF. During operation, they are applied to the surface of the element on which it is necessary to make a hole, and held by hands so that they do not move. In other cases, the furniture template is applied to a specific place or fixed.

The pivoting mechanism has a working surface moving horizontally or vertically. The template allows you to make holes on parts in which the axis is located at an angle. A rotary conductor is used when you need to make a hole on elements having a complex geometric shape.

Tipping devices are needed to work with parts located in different planes. Universal products allow you to readjust them for the production, assembly of furniture of various kinds. They are mainly used in small workshops that make cabinets, tables, chests of drawers in small batches.

Depending on the type of fixture fixation on the surface of the parts, the furniture template is divided into sliding and fixed. Sliding freely lie on the surface of the parts, allow each hole to be made separately. Such devices are considered less convenient. Dockable templates are more convenient to use, although they limit the wizard's actions.

Almost all varieties of devices have a fairly simple design, so they can be made independently at home. This will save money.

The nuances of choice

A furniture template can be made not only from a square and a metal line, other improvised materials will also do. A fixture made on its own can be highly specialized. As an example, products for drilling holes for handles, hinges, other elements. Such devices are more likely to be suitable if the production of furniture is carried out in small volumes.

For a more extensive process of manufacturing interior items by manufacturing a jig, it is recommended to purchase professional equipment. It should be noted that some models can be quite expensive. Using a professional template, the furniture will turn out with high-quality fixtures and will last a long time.

When choosing, it is recommended to pay attention to multifunctional devices that allow not only to make the correct marking, but also to add holes. In the set of equipment there are clamps, interchangeable bushings, rulers, which greatly facilitate the assembly, manufacturing of interior items. With their help, drill holes at the required distance and a certain diameter.

Furniture conductors will allow you to make the correct layout for future holes, drill them at the right angle. Their various types allow you to accurately, quickly and efficiently connect furniture elements to each other. In the end, you get a product that will last a long time.

Video