Which foam rubber used in furniture is better

When choosing upholstered furniture, it is important to pay attention not only to the external component of products, but also to the filler. In order not to have to replace materials during operation, it is necessary to choose high-quality foam rubber for furniture, which will serve for a long time and delight with its elasticity.

Content

Advantages and disadvantages

The material is a polyurethane foam, which consists of many cells filled with air. Raw materials are used to give elasticity to furniture. Many users choose this particular filler as an internal component of sofas and soft chairs. This distribution is due to the following advantages:

- no additives and processing mixtures are used in the production of the material, which means that furniture foam is safe for humans. It does not emit harmful substances and does not cause allergies, so it can be safely used for furniture in a nursery;

- polyurethane foam is not exposed to the fungus, because it has moisture resistance. Even with increased humidity in the room, the chances of mold spores are negligible;

- it is possible to use the material in various temperature conditions and temperature differences. Foam rubber retains its qualities in the range from -40 to +100 degrees;

- Compared to other materials, the filler has improved soundproofing properties, due to which it is able to absorb noise;

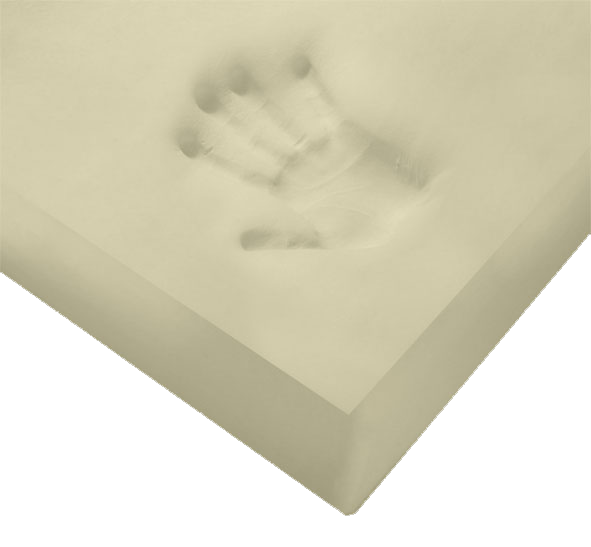

- foam material has high elasticity and at the same time elasticity. He misses under the weight of a person, but also easily restores his shape after a while.

The indisputable advantage of raw materials is its affordable cost. Thanks to this indicator, all upholstered furniture, for which foam rubber is used, has a budget price.

Like any other material, foam has a number of disadvantages, among which:

- low service life: up to 7 years of daily operation;

- hazardous substances are released into the atmosphere during material combustion.

In general, foam rubber has proven itself on the positive side: its dense structure is well suited for sofas, chairs, banquets, corners and other upholstered furniture.

Kinds

The material was widely used in furniture production. Due to these properties, foam rubber is popular for the manufacture of chairs, mattresses. The resulting products have not only high elasticity, but also an attractive cost. Depending on the purpose of the material, it is more expedient to divide it according to the density indicators:

- standard grades - it is made on the basis of a basic polyol; this is the only type of foam rubber used in the composition of one type of polyol.For the remaining subspecies of the material, at least two variants of the substance are used, which give the filler various properties. This foam rubber found its application in the equipment of armrests and head restraints. Its average density is 25-30 kg per cubic meter;

- high rigidity material - for the manufacture of such raw materials, special polyols are used that give the product special rigidity properties. The density of the compositions depends on the additives. If the material has a density index of up to 30 kg per cubic meter, it is used in the manufacture of seats and mattresses. If the characteristics exceed the specified figure - the raw material is suitable for the production of furniture with high loads;

- highly elastic material - the density of foam with high flexibility is equal to more than 30 kg per cubic meter, products from such raw materials are able to withstand a weight of 120 kg. This type is widely used in the manufacture of mattresses.

In addition to the listed types of foam, soft and super soft compositions should be distinguished. They are made from polyurethane endowed with emollient properties. Also, in the manufacture of raw materials, special additives can be used to obtain incombustibility and a viscous structure. In this case, melamine, flame retardant and special polyols are used.

Quality indicators

To understand the quality of the material with which the furniture is filled, it is important to know the basic characteristics by which it is determined. These include the following indicators:

- density;

- strength;

- compressive stress

- markings;

- elasticity;

- permanent deformation;

- degree of comfort.

Each of these criteria needs to be considered in more detail. As already mentioned, the density of the material determines its purpose. The higher this indicator, the greater the load the material can withstand on furniture and the more it will have operational terms.

The strength criterion is represented by two characteristics: tensile strength and the degree of elongation of the material before this gap. At a density of 25 kg per cubic meter, this figure will be 130 kPa (tensile strength) and about 260 percent elongation.

The compressive stress of the material indicates how much force needs to be applied to compress the sample. Rigid varieties of foam rubber are sometimes artificially equipped with strong compression to improve performance, however, when opening cells with air, the material returns its structure.

Foam markings have a separate classification, which will be discussed in our article below. The elasticity of the raw material is determined by the fall of a special test ball on it. They throw it on the material and check the degree of rebound: if the ball bounced high, then the foam rubber is tough and less elastic.

To identify the indicator of residual deformation, the method of strong compression of the sample is used, which in this state is left for a while under the influence of a certain temperature and humidity. At the end of the period, the sample is measured, which is compared with pre-prepared standards. Hard foam will have a small residual deformation.

The indicators of the degree of comfort are also represented by two designations: the coefficient of support and the coefficient of comfort. These criteria are due to the softness of the material, as well as the distribution of the load on the plane.

Appointment of various brands of furniture foam

There is a certain classification, which implies the use of foam rubber of different markings in the production of various furniture. First you need to understand what brand designation is. For this, Latin letters are used:

- ST - this abbreviation means foam rubber of the standard type;

- HL and EL - symbolize foam rubber of hard type and high rigidity variant, respectively;

- HS - the manufacturer marks soft and ultra-soft foam with such symbols; the furniture version can be seen in sofas;

- HR - so highly elastic foam rubber is designated;

- LR - letter designation of material soft and viscous in structure;

- RTC - so the manufacturer designates reticulated polyurethane foam, which is characterized by high porosity.

In addition to Latin letters, numbers are used in symbolism, the first two of which talk about the density of foam rubber, the other two are responsible for the compression stress. For example, if the filler is labeled as: EL 2545, then this will mean the following indicators:

- increased rigidity foam rubber;

- material density - 25 kg per cubic meter;

- the compression stress is 4.5 kPa.

Depending on the labeling, choose the purpose of foam. So, for upholstered furniture, indicators of 30-40 kg per cubic meter in the manufacture of seats and mattresses will become optimal. Characteristics of 25 kg per cubic meter are suitable for children's furniture items. 1620 grade foam rubber is the softest and less durable, it is used for the production of furniture elements with a small load.

Brands 2336 and 2310 are most appropriate for teenage furniture, as they are considered hardy. They can also act as a layer for springs in the manufacture of mattresses. Marking 2536 indicates that this foam is most applicable in the manufacture of furniture. It is the most popular raw material in the domestic manufacture of soft sofas, chairs and armchairs.

Selection rules

Before choosing a filler for upholstered furniture, it is important to decide what kind of product it is. If foam rubber is chosen for a sofa, pay attention to the marking with density indicators from 28 kg per cubic meter and above. If you purchase less dense material, there is a risk that the sofa will not last long.

Use the following recommendations when selecting:

- check the thickness of the foam, for upholstered furniture it should be at least 3 cm;

- learn about the stiffness and elasticity of raw materials: a more rigid option is suitable for seats than for filling headrests or armrests;

- some types of foam do not hold their shape at all, which indicates their low quality, so check this criterion in the store to make sure the reliability of future furniture;

- ask what additives were used in the manufacture of raw materials to prevent allergies to certain substances, especially when it comes to children's furniture.

Pay attention to the marking, it will help to tell a lot of information about the selected foam rubber. You should not save on filler, because high-quality material is the key to a long life of furniture.

Video

(votes: 6, average rating: 3,50 out of 5)

(votes: 6, average rating: 3,50 out of 5)