Stages of creating a do-it-yourself baby bed, how to avoid mistakes

Loving parents worry about the health and proper development of the baby before his birth. And with his birth, the world meets a baby with a huge number of necessary and useful items. Among them, the leading place is occupied by a berth. The best that parents can give their child from the first days of life is a children's bed with their own hands, which is a high-quality and durable design. In this case, parents themselves can choose the form, choose a safe, environmentally friendly material, make beds with drawers a guarantee of quality and reliability.

Content

What will be required for the manufacture

It is not difficult to assemble children's beds with your own hands, especially if the master has the necessary knowledge and desire. It is important that everything is done not blindly, but on the basis of photographs, sketches, drawings with dimensions. The most common types of beds for children are:

- rocking chair;

- bunk bed;

- one-story;

- sliding;

- transformer.

Before making a bed, you need to decide on the choice of material. For the manufacture of furniture use the following types:

- MDF containing binder resins;

- wood-fiber boards (MDF) made with the addition of chemical compounds with boron and wax for strength, resistance to the effects of fungus and moisture;

- plywood, thin layers of veneer glued with organic resins;

- particle boards (chipboard), which are made by pressing wood chips with formaldehyde (a chemical compound used in medicine for disinfection);

- solid oak or pine.

An array of wood is considered the best material for children's furniture, which does not emit harmful substances that cause allergic reactions. Raw wood cannot be used for these purposes, since it is deformed and cracked. A children's bed from an array of do-it-yourself looks great, reliable and durable in operation. Made correctly, it will provide your baby with a comfortable sleep.

Before starting work on making a wooden children's bed with your own hands, you need to prepare everything that is required for this:

- oak or pine boards;

- plywood;

- lamels - flexible planks made of hardwood (acacia, oak), the thickness of which is 15-20 mm;

- slats and timber (for the base under the mattress);

- metal corner for corner joints;

- bolts, self-tapping screws (for fixing product elements);

- varnish;

- stain;

- PVA glue.

The level of complexity of the work on making a crib with your own hands is determined not only by the sizes, drawings, design complexity, design features, but also by the availability of the right tool.You need to get the following set:

- a screwdriver;

- a corner;

- grinder;

- manual milling;

- wood saw;

- grooves for grooves;

- a planer;

- drill with wood drills.

Having collected the necessary materials and tools for making a baby bed at home, you can get to work.

The main details and their preparation

The blanks from which the sleeping place is going to be sanded so that the child does not injure himself. The standard bed layout includes the following details:

- four legs;

- two backs;

- sidewalls;

- lamellas;

- mattress;

- frame.

Parts are manufactured in a specific order:

- first, a tree is selected for workpieces of appropriate sizes;

- then, after all the details have been carefully sanded, the base is marked on them (a sign for the correct assembly of the product);

- marks are made for the grooves, cut into strapping and under the slats;

- spikes are made.

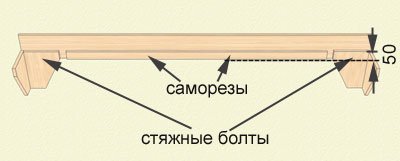

For assembly of finished parts they use special carpentry joints without the use of nails and self-tapping screws. The main purpose of using this method is its quality and decorative features. The surfaces are smooth and beautiful, and the joints are invisible. Fasteners are made as follows:

- the workpiece is marked with a pencil on the border of the shank and the groove;

- the length of the shank is marked with an incision;

- the groove is drilled with a drill;

- excess wood is removed with a chisel;

- files align the edges of the product.

Such fastening is better resistant to mechanical damage, less loosened. Its essence is as follows:

- the connection consists of a shank (spike) and a continuous or blind groove into which it freely enters;

- To fix the parts, carpentry glue is used.

Studded joints fixed with wood glue are firmly fixed due to the swelling of the wood.

The main stages of assembly

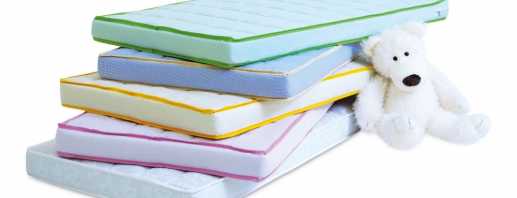

The size of a berth for a child is determined by the width and length of the mattress. They are standard and equal to 1200x600 mm. According to these parameters, a wooden crib is made by hand. The mattress is not made independently, but purchased, because for its manufacture it is necessary to follow orthopedic requirements. In its production, the needs of a growing organism in a full and healthy sleep are taken into account. For this, attention is paid to the design of the mattress forming the spine of the child:

- infants choose foam models;

- Children over four years old need to install a mattress with a spring unit. It provides an even distribution of the baby’s weight over the entire area.

For small rooms, the bed can be made so that in the daytime it serves as an arena. Starting to assemble the crib, carefully examine all its details so as not to miss chips and other possible defects that could cause injury to the child.

Assembly work begins with legs that differ in size from each other. For the head they are longer than for the opposite side. The high backrest is designed for pillows that can lift. Then, using the drawing and sketch of the cots, the frame is assembled, the next steps will be the assembly of the backs and canopy structures. The crib frame includes:

- bed base;

- backs at the head and foot.

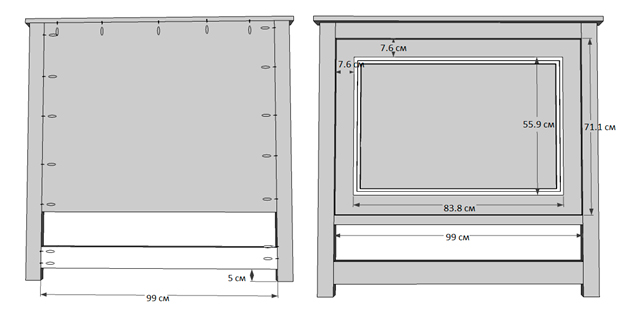

The supporting frame is made of timber, divided into 6 workpieces of the same size with grooves (25 mm) for lamellas. Plates are designed for ventilation of the mattress, they are inserted into the prepared grooves and fixed with carpentry glue, forming a lattice. The distance between them is 5 cm. The base of the crib is made of four boards with a thickness of 35 mm and a width of 7 mm. Children 4-6 years old make the height of the lower part of the crib equal to 35 cm.

When calculating the backs, the width of the bed is added to the thickness of the board. At the head of the crib are installed slats and furniture plywood panels that fill the backs.The vertical and transverse bars of the backs are connected. All connections are fixed with PVA glue.

The frame is assembled from prepared boards:

- the mattress is attached to the bed frame by means of studded joints;

- then fasten the sides, fencing, the limiter for the crib, not allowing the baby to fall;

- the front side is made one third lower than the rear, for the convenience of caring for a child;

- Using a square, angles should be checked, which should be 90 degrees;

- the sides are allowed to dry from glue. Its remains are cut with a knife.

For ease of movement of the crib around the room, you can supplement the design with wheels. Creating a comfortable rest for the child, a canopy made of their own bunches is hung over the crib. For him, they make a mount in the form of a roof. The design resembles a cozy fairy-tale house in which the baby feels protected. For this, the design of the back of the crib is adjusted:

- the railing is made a little higher. With a saw or hacksaw, cut off their top;

- the base of the roof of the house is attached to them;

- the last step will be fixing the ridge, which will connect the roof to the base.

Do-it-yourself canopy for a baby bed will become reliable protection. This is a great addition to a sleeping place made by a caring dad.

Decoration Methods

To make a home-made children's bed completed after assembly, it is decorated in various ways. The first step to give the product an aesthetic appearance is putty, which is carried out as follows:

- the composition smears all cracks in the joints;

- after drying, the treated areas are carefully sanded with sandpaper.

The collected bed is treated with stain. This is done not only for design purposes: the product protects the product from excessive moisture. On top of the stain apply varnish on 2-3 layers or wax for wood.A crib made for a small child is soaked and covered only with natural products that do not contain toxic substances.In addition to this method of decoration, there are other varieties of it. To give the product a finished look, the bed is covered with an upholstery fabric for furniture:

- details for all elements are cut out;

- process these parts;

- they are decorated in such a way that the fabric lies evenly, there are no folds and creases.

One of the types of crib decor is jewelry in the form of wraps made of thin fabric. They are designed to protect children's sleep from external influences. Before you make a canopy over the crib, you need to get acquainted with its purpose and rules of attachment:

- it will protect the child from drafts, therefore in the summer period light enough fabric, in winter it should be denser;

- canopy will protect the baby from unnecessary prying eyes;

- protects from annoying insects in hot weather;

- hide from too bright light.

With his own hands, it is made simply. The fabric is strung on a thread and spreads by assembly over the baby’s bed on various types of fastening (around the perimeter of the bed, in the middle, at the head of the head). Children from 3 years old should not hang a long canopy with poor attachment over the bed, as the child, starting to move actively, can get entangled in fabrics and fall.

The nuances of making a model with drawers

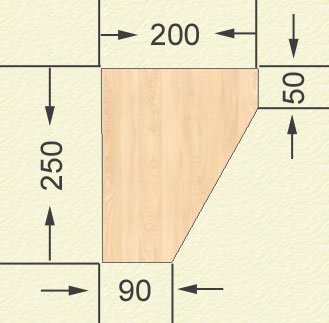

Parents have different attitudes to the design of cots. Some people like the space under it to be free for easier cleaning, while others prefer functional children's furniture. Such parents are interested in how to make a bed with drawers in the child’s nursery with their own hands. To make a drawing of such a bed, you need to take into account the following points:

- type of boxes - they come in two types: on rails or on wheels.With laminated floor surfaces, the second option is not entirely suitable, since the percentage of floor wear will be more significant;

- the number of boxes, which can range from 1 to 3;

- the base of the bed, which are two. If it is a metal frame on the legs (orthopedic base), then a box for boxes will be formed around it. If the mattress lies on the slats or chipboard, then the bed box will be bearing;

- size (length and width of the berth), which can be standard or custom-made.

Calculations can be made by taking the standard standard bed as the basis, but the front bar will be slightly narrower in width so that the depth of the built-in drawers is greater. A simpler assembly of furniture is considered an insert design with drawers. With the orthopedic base of the bed, it is necessary to place the boxes in the existing height, as well as round the legs with a frame. With a plug-in design, the indent from the edge of the box increases. The best model is a bed with drawers having wheels, since in this case you can do without a plug-in design. Just install the partition in the center.

You can highlight the design features of beds with drawers:

- drawers are fixed 10 mm above the floor (with carpets more);

- the front bar is fixed last, as it covers the insert design.

The project for the manufacture of a crib with their own hands is individual in nature, it depends on the ideas of the master. This work is associated with a whole range of subtleties and nuances that depend on the purpose of the product, its size, shape and design. Each master in its manufacture faces a lot of problems. But this work always has a noble ultimate goal. All problems are forgotten at the sight of the happy smile of a child for whom it was made with great love.

Video