Purpose of furniture futurki, nuances of choice

The quality of furniture products throughout the entire period of its use is determined not only by the material and surface cladding, but also by the trouble-free operation of the front, internal mounting hardware. An important role in connecting the parts of the structure is played by a furniture futurka, which is the simplest part that provides rigidity and stability to collapsible elements.

Appointment

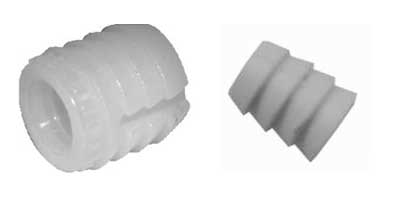

The connecting product, due to its design features, is an important element in the assembly and repair of furniture. Furniture furniture is a fitting with metric internal thread and external screw. It is widely used when installing shelves in cabinet, kitchen furniture, as a base for hooks.

The part is well suited for joining complex planes, especially with a rectangular end screed, when assembling and disassembling furniture from chipboard, MDF and soft wood. The part, providing reliable fastening, is quite technologically advanced, has the correct thread pitch, diameter size, low degree of surface roughness, and tightness.

The main purpose of the part is screwing or driving into a prepared hole on the surface. The hardware, coinciding with the passage along the diameter, thread, provides an accurate, durable connection, does not allow gaps and distortions between the fasteners. The product, even with an increase in contact area, tolerates load well.

The product is technologically advanced in its design features: it effectively reduces time costs, and contributes to the quality of furniture manufacturing and repair. To improve the corrosion resistance, parts are coated with chrome or zinc.

The life of all furniture depends on the quality of the product. The mismatch of the thread or diameter even by a millimeter can cause a malfunction of the sliding, extendable, transforming parts.

Varieties

The product for various types of connections can be of different sizes and diameters. Differing in shape, direction of internal and external threads, combining stealth, it provides multiple disassembly of the product, preventing its deformation. A small part that can be made of different materials serves as a mount and represents:

- hardware with a groove for a hex wrench or screwdriver;

- expandable and expansion adapter, for self-tapping screw, nylon;

- a foot with a latch, for attaching furniture supports;

- hardware with a spacer ball, for eccentric, conical couplers, using a rod, screw.

Today, a special place is occupied by a plastic shelf for furniture. Inexpensive hardware, easy to use, easily cuts into the hole of the surface, does not deform, due to the particular arrangement of the thread and its direction. The main advantage of the part is reliability and high load capacity.

Materials of manufacture

Threaded products for various types of joints are made of corrosion-resistant steel, brass, non-ferrous metal alloys with nickel, anodized, zinc, chrome coating, high-strength plastic, aluminum. Most often, when dismantling, assembling, repairing furniture, steel furniture legs are used. Being reliable elements for fasteners, they have several advantages:

- high strength throughout the entire operational period;

- increased corrosion resistance due to the high content of alloying elements;

- ease of installation, which contributes to a tight connection;

- have a small percentage of defect;

- details are steady against temperature differences.

Today in furniture production plastic futors are considered to be no less demanded. Having high wear resistance, reliability, they can easily replace metal products. Plastic hardware has good impact and mechanical strength, low weight, density, withstand various loads without changing its shape, without requiring special efforts in connection.

The dimensions of the casing for screws, nuts, screws, self-tapping screws, rods, studs depend on the nature of the work performed and the characteristics of the clamping elements, furniture material. Their value should not interfere with the installation of other fittings.

Nuances of fastening

An adapter with a through hole, regardless of the material of manufacture, allows the rotational action to be carried out uniformly, translationally, without much tension. The main difficulty in mounting the part is maintaining high accuracy when drilling holes.

During use of the part, special attention is paid to its outer and inner diameter, thread pitch. In contact with threaded hardware, they must be combined. When installing the foot, it is necessary that:

- the centers of the landing hole and the part to be joined were aligned so as not to break the hole, not to impair the strength of the connecting elements;

- when manually drilling a non-through hole, care was taken not to damage the face of the formation;

- When screwing the part into hardwood, a special grease or wax was used to facilitate screwing. Tightening force is regulated by protruding excess substances;

- the hole was drilled perpendicular to the surface of the panels to be joined, in order to avoid their creeping during the installation of the screed.

When working with a fastener, an electric drill with a soft start function is usually used, a furniture conductor for drilling, which is very popular among furniture makers. Using a unique device, drilling for fasteners, fittings are performed with high accuracy and speed, which makes it possible to correctly fix the foot.

The main structural element is a sleeve designed to guide the drill. The tool is made of wood, MDF, chipboard, metal plastic, which greatly facilitates the installation of threaded fittings made from various groups of material.

Video