Varieties of wooden swings, DIY manufacturing tips

Swing is a favorite pastime not only for children, but also for adults. Placing them on the personal plot of a private house or cottage, it is necessary to ensure safety. To make independently wooden swings of the simplest design is quite affordable even for a beginner. For more interesting and complex models, you will need detailed descriptions, diagrams, master classes.

Content

Varieties of designs

The first step to creating is choosing a place and type of structure. There are more than 20 varieties of garden swings made of wood. Their differences lie in the design features, sizes, purpose, type of seat. The most common types of mobility and weight are:

- Stationary They are characterized by large sizes, firmly fixed to the base: it is either poured with concrete or buried in the ground. This type of wood swing can be installed in the gazebo. In this case, the base is mounted on the floor.

- Wearable. They are lightweight and compact in design. It is stable, does not require fixing. The swing is easy to carry thanks to its light weight.

- Collapsible. Such products consist of a frame and a suspension structure. A special type of threaded fasteners facilitates the multiple assembly and disassembly of the swing. The compact size when folding will allow them to be transported in a car and taken with you to nature.

- Outboard. Models of this type of swing often do not have a frame. The easiest option is a rope with a wooden plank as a seat, which can be hung on a tree, to a beam on the veranda or horizontal bar in the house. Complex types are attached with hooks to the ceiling. An example is factory-made hanging rattan nests or do-it-yourself wooden swing benches.

In terms of weight, there are adults and children. The latter are commonly used for entertainment. Swings for children made of wood are almost always single, while for older generations of the family romantic double models are installed with seats opposite, as well as multi-seat in the form of sofas.

Among the varieties of swings, installed at the cottage with their own hands, designs with sun protection are very popular. This can be a canopy of straw, an awning on a frame of planks or a visor made of plastic. Products without such devices are best placed in a shady place. According to the structure of the frame, there are several types of swings:

- U-shaped. Consist of two vertical posts and one horizontal crossbar. Stability depends on the reliability of fixing in the ground (or other basis). To create such a wooden swing with your own hands will require a little time and materials.

- L-shaped.It is a structure of two pairs of bars and a transverse crossbar connected at the top point. The model is stable and does not require careful strengthening.

- X-shaped. This design has a low fastening of the supports, as a result of which jumpers are formed on which the beam is laid horizontally. The swings are simple in execution, but require additional reinforcement at the base.

- A-shaped. They are characterized by increased stability due to additional structural elements - sidewalls that increase reliability. They are best adapted for a full-fledged complex for children with ropes, ladders.

Before you make a swing, you need to prepare the materials. It is necessary to decide in advance which types of wood are better to use, how to process the surface. Reliability, durability, and product safety depend on the choice of source material.

Materials and tools for manufacturing

The choice of material depends on the design and type of structure. Homemade swings are made from boards, beams, euro pallets, logs. The latter must be used strong, fairly solid. Coniferous types of wood, such as pine, larch, are well suited.

A set of necessary tools:

- chainsaw;

- electric jigsaw;

- plane;

- drill with a drill;

- screwdriver;

- screws with a ring;

- hammer;

- eye bolts.

The ends of the logs to be buried must be protected from decay, for example, by resin. As a suspension, chains or strong ropes with a metal core are used. Not only excellent seats are made of boards. With proper dexterity, it will be possible to create a full-fledged A-frame from a double fabric, which will provide good strength and reliability of the structure. The seat can be in the form of a bench, chair, sofa with armrests. In addition to the standard set of hammers, nails, a screwdriver, emery is also needed. The varnish to protect the wood from destruction will make it safer and smoother to the touch.

Swing made of timber is stable, and fitting parts is easier due to its regular shape. For manufacturing, either rounded or non-rounded building material is used. A standard cross-section of 40 x 70 mm will allow you to create an option with good load-bearing capacity and a sofa seat. The material must be sanded, treated with fungicidal and antiseptic solutions. Metal brackets, rigging, chains are added to the basic tool kit.

Suspended structures made of Euro pallets are an economical way to create a cozy place to relax. It is enough to choose a wooden pallet, process it, cover it with a mattress, blanket, pillows and hang it on the ropes from the ceiling of the gazebo or canopy. It turns out a cottage version of a swing bed. You can slightly complicate the process by adding low sidewalls, the headboard, or convert the pallet into a small sofa on suspension chains.

To create such auxiliary materials and tools will be required:

- hammer;

- spanners;

- metal corners;

- wood drills;

- electric jigsaw.

Durable hooks or carabiners are used for secure attachment. Do not forget about pre-treatment with liquid preparations for mold, primer and paint.

After determining the dimensions, choosing the design and materials for future swings, you need to choose a drawing or create it yourself. It should be carefully worked out: errors that crept into calculations made hastily lead to negative consequences. Safety should come first.

Drawing creation

Drawings of wooden swings for a summer residence with their own hands create according to exact parameters. It is necessary to take into account such factors as the strength of materials, the stability of the final structure. The size of the structure, as well as the swinging amplitude with the suspension length, respectively, will depend on the chosen location.Without engineering skills, it is possible to make a competent drawing, but only with the utmost accuracy, accuracy of measurements of raw materials, observing the recommendations of experienced craftsmen. Advice:

- The first thing that needs to be done is to draw a diagram of the swing support.

- Based on the selected frame type, material characteristics (length, thickness, bearing capacity), calculate the height and width of the supporting structure. Enter data in the drawing.

- Separately simulate a seat pattern indicating the length, width, height, presence of a backrest, armrests.

- Additionally, make a drawing of fixtures.

It is at the modeling stage that it is possible to identify flaws and design weaknesses. It is necessary to provide for the reinforcing elements: stops, jumpers, additional fasteners. Drawings necessarily include:

- frame type (for complex structures - in several projections);

- height and perimeter of the base;

- list and localization of reinforcing elements (spacers, jumpers, kerchiefs);

- type, number, size of seats, mounting methods;

- length, thickness, suspension material.

It is much easier to use ready-made schemes for the manufacture of swings for the garden. They are painted, well designed. Such drawings, if necessary, are made in two or more projections, not only numerical parameters of dimensions, but also explanatory signatures go to each part. Additionally there is a list of tips and useful tips on how to make a garden swing.

DIY workshops

Step-by-step instructions help to bring popular models to life. Making a garden swing made of wood with your own hands will not be difficult even for a person who does not have a carpenter education, if you carefully follow the recommendations. You can make children's and adult models with different frame designs.

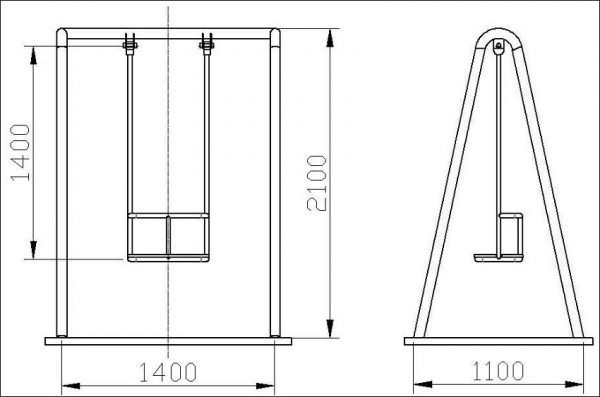

Baby A-shaped

The preparatory phase involves drawing the diagram. Dimensions are determined based on the age, height and weight of the child. When calculating, you should use the basic rules:

- The height of suspension of the seat above the ground is not less than half a meter. This will allow the child to independently stop the swing, while there will be no interference with riding.

- The seat width for comfortable use should not be less than 60 cm.

- The length of the suspension is 1.6 m, which will allow you to swing standing up if you wish.

- The height of the supports from the ground to the crossbar is determined by the thickness of the swing seat and is in the range of 2.1-2.3 m.

First you need to prepare materials, tools. For the A-frame, a beam is suitable as a support. Prerequisite - dry material without signs of spoilage.

There should not be any surface defects on the timber in the form of knots, holes.

A complete list of what is needed for making a swing:

- Four beams with a cross section of 80 x 80 cm or 100 x 50 cm as a support, plus one of the same on the crossbar.

- A board measuring 60 x 30 x 2.5 cm as a seat, plus an additional three to four pieces on the armrests, a backrest for a small child (mandatory up to six years).

- Stainless steel suspension chains or cables, strong ropes - 2 pieces.

- 250 pieces of screws 50 x 3.5 mm and 50 pieces 80 x 4.5 mm for fastening the frame.

- Hooks (carabiner, steel corner) for attaching suspensions.

- Primer for wood, varnish, paint, fungicides against fungi.

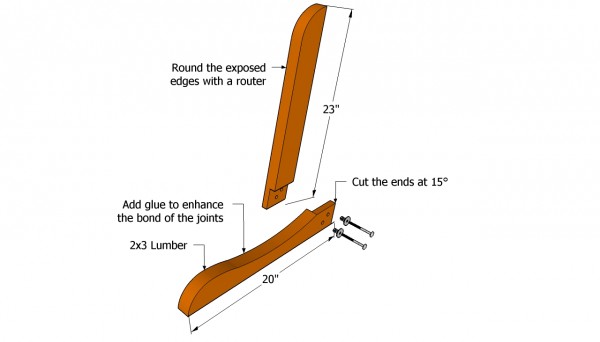

Of the tools you will need: a planer, a screwdriver, an electric jigsaw or chainsaw, wood drills, a plumb line, a level, a tape measure, a grinding machine. After the preparation of materials and devices, you can proceed with the implementation of the plan-scheme:

- The site selected for the swing needs to be cleaned from grass, debris, bushes nearby, then leveled. If necessary, you can concrete the site (increases the risk of injury when falling) or make a wooden floor in case of further expansion to the children's complex.

- It is necessary to prepare the bars: sanded to reduce the risk of splintering, treated with fungicide and primer.

- The assembly of the A-type swing frame is carried out directly on the ground.To begin with, cut off a corner at one of the ends of each of the four bars, then fit the paired elements tightly and fasten with self-tapping screws. Install supports on the ground. For additional stability, you can use staples, a rod or dig a bar into the ground, tarring the ends.

- Install the crossbar, fixing it with a corner or a suitable nozzle-nozzle.

- Put together a seat from the boards. You can improve the model with a back, armrests or use improvised materials: tires, pallets, old children's chairs.

- Fix the gimbal to the upper crossbar. As a fastening, a rope knot or more reliable methods are used: an anchor, a carbine, steel plates, special swing units.

The final stage is decorating the finished structure - painting with paints that are resistant to external influences. They must be non-toxic, safe for the child. Mandatory care includes a periodic check of the connection nodes, structural stability, and the absence of damage.

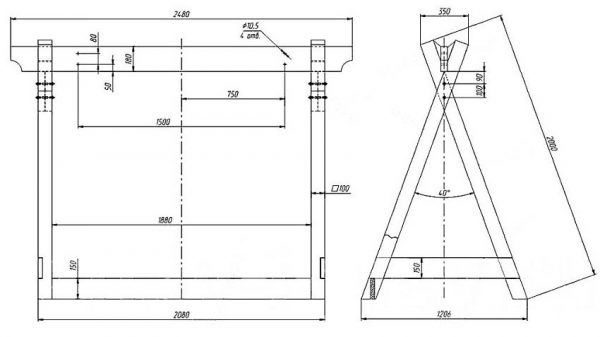

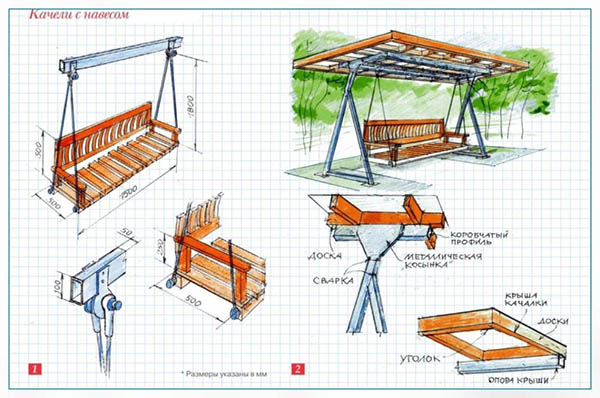

With a canopy

A canopy will help protect the place of rest from the weather. A multi-seat swing is used as a seat - benches suitable for family hanging out. Designs of this type are made on the basis of the A-frame. To the set of tools described in the first master class, you need to add:

- As a support - 5 two-meter bars measuring 140 x 45 mm and two parts on spacers with a section of 140 x 45 mm, lengths 96 and 23 cm.

- For the bench - bars with a section of 70 x 35 mm. You will need: 2 parts 95.5 cm long, 4 60 cm long, 2 120 cm long (seat) and 27.5 cm long (armrests). Also needed are three trims 70 x 25 mm for a 130 cm backrest and 8 trims for a 130 cm seat.

- Two canopies of timber 70 x 35 mm, two meters and 90 cm long.

Step-by-step execution consists in creating a support, a swing bench, a canopy. As the latter, you can use a waterproof awning. This option will protect both from the scorching sun and rain. Master Class:

- It is necessary to make slant cuts at the ends of the supports. It is most convenient to do this using a square with rafter pins.

- Connect the swing supports to each other and the transverse beam. Next, the spacers need to be cut at an angle and attached at a distance of 15 cm below the upper beam. Fix the lower bars half a meter from the ground.

- Assemble a rectangular frame for the awning. Fix it with screws. The frame is fixed to the upper struts in the rear and in the middle under a slight slope for draining water.

- Assemble the seat from the parts with a hammer and nails: first - the frame, then fill the base and back straps.

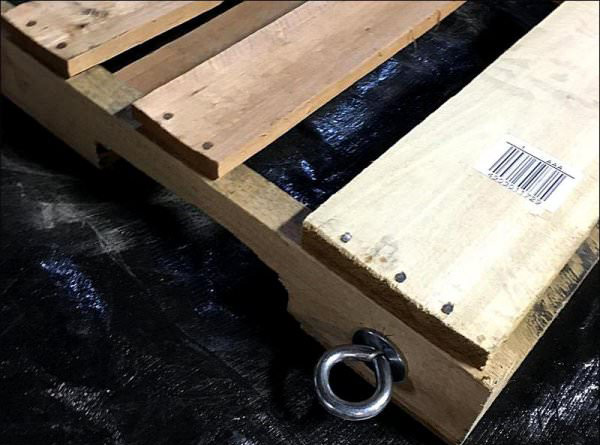

- Hang the chain bench using eyebolts and snap hooks. Chain length - 110 cm.

- Attach the canopy to the frame.

In addition to the awning, you can use plastic sheets, metal tiles, corrugated board as a protective roof. Finished products must be protected from the damaging effects of weather conditions: primed, painted. Do-it-yourself garden swing made of wood with a canopy ready.

For arbor or porch

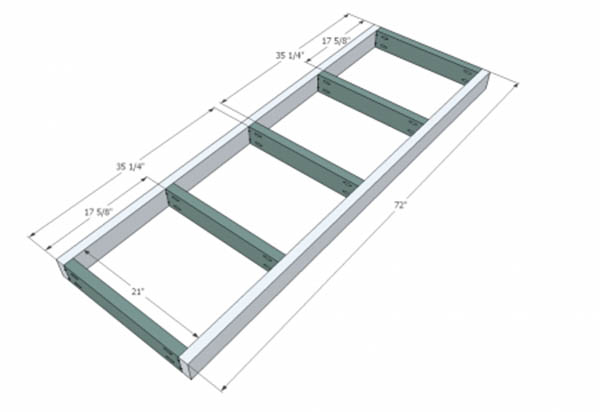

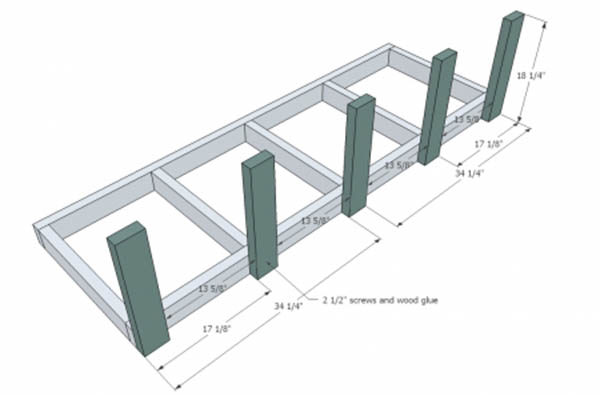

Hanging swings in the gazebo, on the porch, porch or terrace are not only a place of relaxation, but also an excellent element of decor. Most often they are made in the form of sofas. The main condition is the presence of a strong support beam, to which suspensions are attached. The set of materials and tools is reduced due to the fact that there is no need to make supports. For a seat with armrests and a backrest measuring 1400 x 600 you need:

- a bar with a section of 70 x 40 mm for the seat frame: 2 pieces with a length of 1400 mm and 3 pieces of 600 mm each;

- slats 70 x 25 mm in 1400 mm - 2 pieces and in 600 mm - 2 pieces for the back;

- two bars in 270 mm and 600 mm long for armrests;

- boards 600 x 200 x 30 mm - 3 pieces, 600 x 100 x 2.5 mm - 4 pieces for the back;

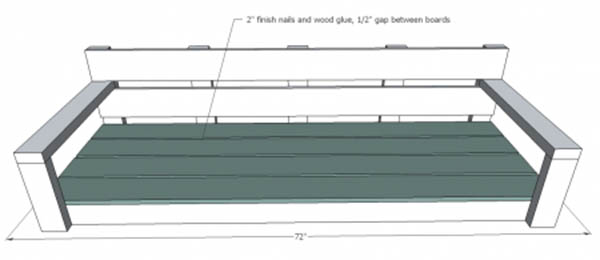

- boards 600 x 200 x 30 mm - 8 pieces for the base of the seat;

- ropes with a metal core 3 m long - 2 pieces;

- metal hooks - 2 pieces;

- hammer, nails, screwdriver, screws;

- mattress, pillows, bedspread.

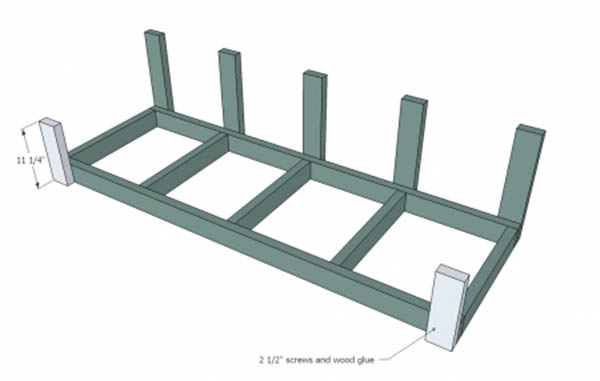

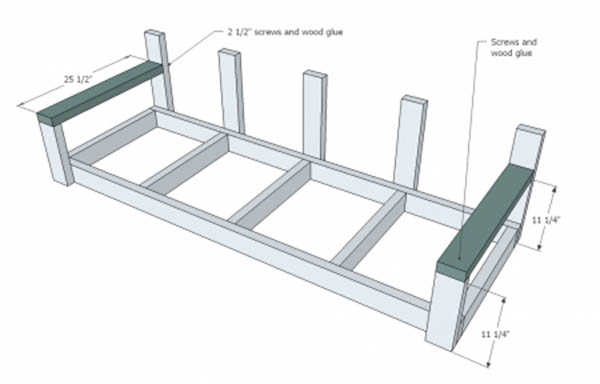

A step-by-step instruction for assembling such a sofa is to create a framework for the base, back. Parts are connected by nails, attached to the beam with metal hooks. Work Stages:

- Put together the base of the sofa from the bars. Additionally reinforce with metal corners.

- Make a backrest frame, connect to the base.

- For the back with a cross-shaped pattern from the boards, it is necessary to make corner cuts, as well as cut out the grooves in the lower bars for a beautiful overlap. Boards are nailed to the bars of the frame.

- Make armrests.

- Attach the ropes to the base of the sofa, additionally fix on the armrests.

- Drive in hooks, suspend a swing sofa.

The last stage is decoration. Textiles - a mattress, pillows, bedspreads will give a cozy look to a sofa. An easier way to create a hanging swing on the porch or porch is to use improvised materials, such as an old wooden crib. It must first be strengthened by knocking down the frame of the base and back with strong bars. You can use pallets to create a swing bed on suspensions in the gazebo or on the terrace.

From pallets

A do-it-yourself swing made of pallets is very popular among beginners due to the minimal time and material costs. One or two pallets, suspensions and fasteners are enough. Pallets should be strong, without signs of decay, mold, cracks. As rigging, either rigging devices or carbines are used. Tools for making:

- hacksaw;

- pliers;

- drill;

- screwdriver;

- spanners;

- plumb bob;

- spanners;

- level, roulette.

The step-by-step instruction of the simplest hanging swing from pallets includes preliminary grinding, processing by impregnation, and paint. Then the ropes are fastened with the help of the simplest “horse knot”. The construction is suspended either to the gazebo beam or to the A-shaped support. They will add comfort to the pillows, the headboard and sidewalls, which turn the swing into a sleeping place in nature. Using the corners, you can create a sofa. A pair of bars is recommended for use as armrests.

Pergola style

The pergola swing is a mini-gazebo structure on four pillars with a roof. Sometimes they are additionally closed from the sides with openwork or dull walls to protect against wind. The seat is usually double or triple in the form of a bench. The stability of this design is much higher, but the list of necessary materials is greater than for traditional A-shaped swings with a canopy. For a model measuring 3000 x 1000 x 2100 mm, a number of materials will be needed:

- Four support posts with a section of 90 x 90 mm, 2.1 m high.

- Two upper crossbars 90 x 90 mm three-meter length.

- Four side bars 90 x 90 mm in 1000 mm long.

- 8 bars with a cross section of 22 x 140 mm in 1020 mm long for a canopy.

- 8 dowels with a cross section of 10 mm and a length of 75 mm.

For the seat you need bars 90 x 90 long:

- 660 mm (2 pieces)

- 1625 mm (4 units);

- 375 mm (2 pieces);

- 540 mm (2 units);

- 1270 mm (2 pieces).

You will also need 3 bars of 140 x 30 with a length of 310 mm and 1685 mm, with a section of 90 x 30 mm with a length of 560 mm in the amount of two pieces for the armrests. The parts are interconnected by means of dowels. Swing fasteners must be used in stainless steel.

Assembly and installation steps:

- Creating a pergola. Assemble the parts by fastening the support posts together using the side rails, and then the front and rear.

- Install the frame, nail additional side posts at the base of the swing, if necessary.

- Assemble the swing seat.

- Make a canopy by stuffing the slats at an equal distance from each other. So that it protects from rain and sun, you can lay on top an awning, tarpaulin or metal tile.A more aesthetic option, a live canopy from weaving plants such as grapes or hops, is fraught with proximity to insects.

- Attach the suspensions to the bench and upper crossbar.

The last thing that needs to be done is to decorate the structure, namely to varnish or paint. It should also be treated with protection against rot and fungus. Openwork screens can be attached to the side rails as walls.

Double-legged logs

Such swings have a U-shape, reinforced double legs in the form of lower struts. All this allows to improve stability. Logs should be sanded, sanded, varnished. Of these, support beams, a crossbeam, four spacers, two for each support, must be prepared. The parts are fastened together with metal brackets.

Step-by-step assembly of log swing with double legs:

- Soaked logs should be impregnated with a special composition, varnished. The ends to be dug into the ground must be gummed or pickled with machine oil.

- Make inclined cuts on the stops.

- Dig support posts into the ground.

- Attach the stops.

- Put the crossbar, fasten with brackets.

- Attach suspensions, install a seat - a board or a chair.

The considered methods and master classes on creating a swing have their pros and cons. All of them vary in complexity of execution and materials. Having studied them, you can quickly understand how to make a garden swing from a tree yourself, and a variety of schemes and ready-made drawings will facilitate the task of arranging a personal plot.

Video