Sandwich furniture review, material features and applications

The furniture industry does not stand still, engineers are constantly developing new ideas to improve the characteristics of manufactured products. The relatively recently invented technology for the production of sandwich panels for construction work quickly gained popularity. Sandwich furniture is made of panels made on the principle of a sandwich. They are very durable and weigh very little. Such panels can be made in any color and allow the owners to get very interesting furniture sets at a low price.

Features

Sandwich panels are an incredibly popular material used for insulation of building envelopes, slopes and furniture. The main feature of the sandwich panels is their design, resembling a sandwich. Between two flat sheets of solid material is a lightweight filler. For the manufacture of furniture designs, one of the types of sandwich panels is used - tamburate. This material has a number of features taken into account when designing a project:

- The simplicity of processing panels allows anyone to cut intricate shapes out of material without using special tools;

- Thanks to a loose filler, it becomes possible to perform hidden installation of wiring in computer tables. Fasteners can be easily hidden inside the furniture, while it does not lose its beautiful appearance;

- Sandwich panels can be combined with other materials. The same fasteners contribute to this. But for very thin sheets, you will have to use special built-in fasteners;

- Strength is ensured by the design features of the internal filler, it has many stiffeners, which allows the material to withstand heavy loads without deformation;

- Thin panels are able to bend under the action of vertical loads, while they do not lose their strength and rigidity. This feature allows you to easily produce bent furniture elements;

- A wide selection of exterior decorative coatings allows you to implement the most interesting ideas of designers;

- With a large volume of parts, the products have a very small weight. Due to this feature, impressive designs can be made from sandwich panels, and at the same time they will not cause difficulties during transportation;

- The low cost of the material makes it affordable for most people.

Varieties

Sandwich panels are divided into several types depending on the size of the plates and the type of further processing, that is, the characteristics of the front surface:

- Products without cladding require additional coating with a paper-layered layer to give an aesthetic appearance.Covering the slab with veneer allows you to create an element from a sandwich panel that is indistinguishable from a solid wooden product. Veneered facades of cabinet furniture ennoble the design of the economy option;

- Slabs decorated with the final coating are still at the factory. The facing material in this case is PVC film, paper coating or natural wood veneer;

- Ready to use decorative boards. They are ready for installation work and do not require additional processing.

Depending on the outer coating, the sandwich panels will have different properties. The outer parts of the furniture sandwich are sheets of chipboard or MDF, the thickness of the sheets is in most cases 3 mm. This is enough to ensure the required strength of the product.

Facing the edge of the sandwich panels is similar to a similar operation carried out in the manufacture of solid wood boards or chipboard. The edge in the case of the manufacture of a tamburate, in addition to performing a decorative function, will serve as an additional element stabilizing the side surface. Due to the presence of a decorative edge, the joint between the surfaces becomes invisible.

Some plates are made without cladding, these products are much cheaper and the owners can independently choose the color of paint for their furniture. Outside of such boards is HDF or MDF; paint can be applied directly to the boards without any preparatory work.

Tamburat is used for the manufacture of large pieces of furniture that do not carry significant loads. This material perfectly imitates large wood parts, with significant material savings. Sandwich panels can replace wood or particle boards in visible areas of furniture. Another option for the use of panels is the manufacture of solid sets of furniture made entirely of tambourate, such a sandwich furniture will weigh little and at the same time look good.

Several types of products are made from tamburate:

- Worktops can be made of material of different thicknesses, due to which various designs and design options are created;

- Shelves can be located both inside cabinets of the same material or complement furniture made of solid wood;

- Cabinets made of tamburate, contrary to the opinion of the fragility of this material, are in no way inferior to furniture made of MDF or particleboard;

- Sets for a children's bedroom will not only look good, but also meet all sanitary and hygienic requirements;

- The furniture hollow inside allows you to place wires inside it and not clutter up the room with them, this feature has made sandwich panels popular in the manufacture of office furniture.

One of the restrictions on the use of sandwich furniture is a ban on its installation in rooms with high humidity.

Materials of manufacture and filling

All panels of the tamburate consist of several elements:

- Facing parts;

- A frame consisting of a pair of horizontal and vertical bars;

- Embedded elements located in the places of fastening of accessories. They are designed to provide strength;

- Aggregate.

The inner part is made of cardboard made in the form of honeycombs. This design provides the greatest strength of the panels. Honeycombs made of thick cardboard are enclosed on the sides with sheets of chipboard or MDF, the thickness of the facing part may differ depending on the type of panel from the tambourate. Thanks to this technology, the owners and guests of the house with such furniture, not only in the photo, but also in life will take furniture from sandwich panels for real wooden products.

An adhesive machine and a hot press are used to fasten the parts of the structure. After assembling the panels, they become one.

When making furniture from sandwich panels, it is necessary to choose the right fittings. If the products have embedded slats and facing panels with a thickness of at least 8 mm, then any accessories are allowed. It may be suitable for mounting integral parts.It is more difficult to choose accessories for elements without embedded slats or with thin cladding parts, it must meet a number of requirements:

- Fittings must connect the outer parts of the plates with the internal filler;

- The inner layer should not be deformed during operation;

- Fixation to thin cladding panels must be ensured.

The cost of special accessories is expected to exceed the price of standard accessories, but their use together with thin plates is unacceptable and will lead to breakage of new furniture. Cellular aggregate is the most important part of the panels, and structural strength depends on its quality. It fits inside the frame manually and is attached there. In places of installation of fixtures for fittings, it is bent. After assembly, the structure is pressed, and then horizontally laid for at least a day.

Selection rules

A beautiful setting for little money is an example of the proper use of furniture sandwich. Worktops that visually mimic expensive wood or stone look very impressive. And cabinets with rich content can afford people even with a small income. To ensure the durability of the products, you should responsibly choose the panels:

- Panels should be selected in accordance with the expected loads on them;

- When buying material, you must pay attention to visible damage to the products. Chips, pressed parts and a coating extending from the base are not allowed;

- The fittings placed on the furniture should correspond to the thickness of the product.

Following these simple rules will help ensure the purchase of a quality product. In addition to the choice, it is important to observe the operating rules: the material does not tolerate excessive moisture and very large point loads.

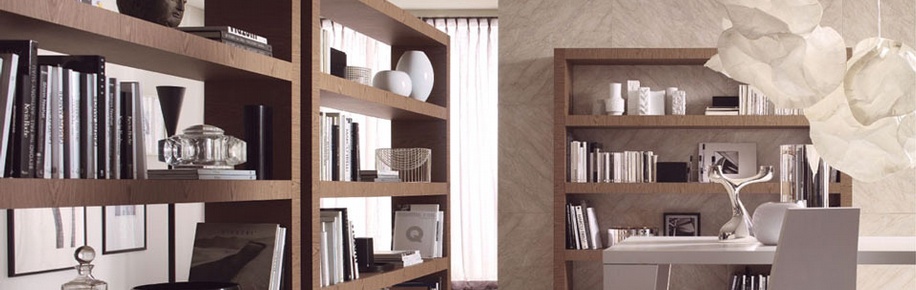

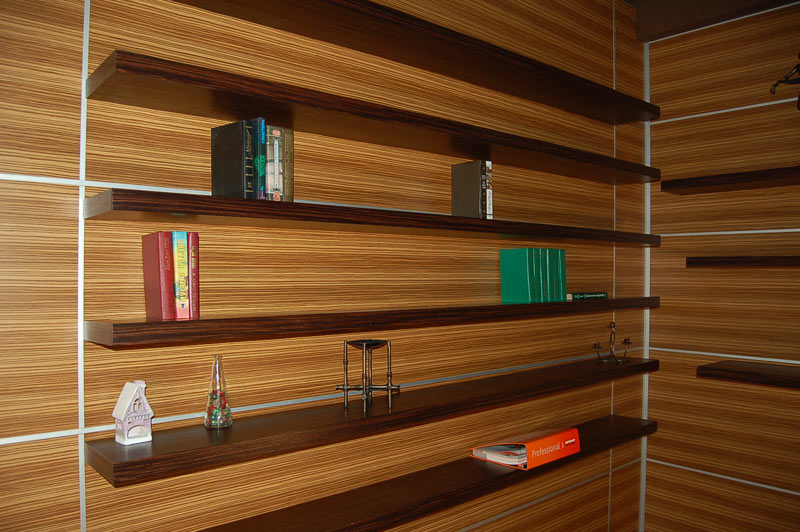

A photo

Video