Varieties of furniture panels, main methods of application

Furniture production has gone a long way and today you can make and assemble headset items yourself. To do this, furniture panels were invented - ready-made panels of wood material used for self-designing objects. This is a great solution for people who decide to make furniture with their own hands.

Content

What types of manufacturers offer

In simple terms, a furniture panel refers to a variety of parts for assembling furniture. These parts are already ready-made sold in stores, it remains only to purchase their necessary quantity. The main feature of these devices is the possibility of using not only for home furniture production.

The most popular panels for furniture today can be called 2 types: products from MDF and options from chipboard. The former are considered to be of better quality, the latter - win in the price category. To understand a large number of products, it is worth considering what types of manufacturers offer:

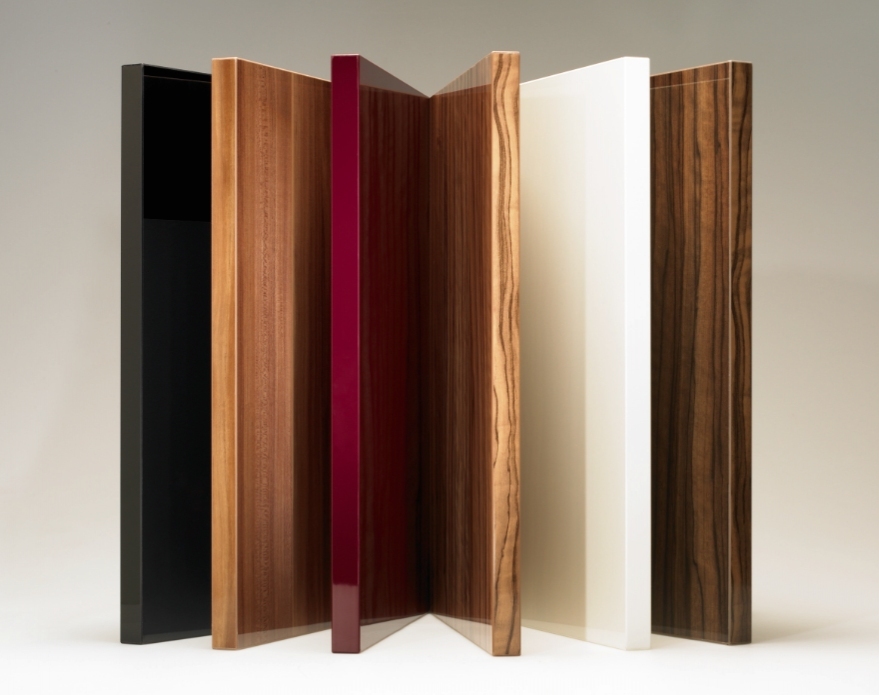

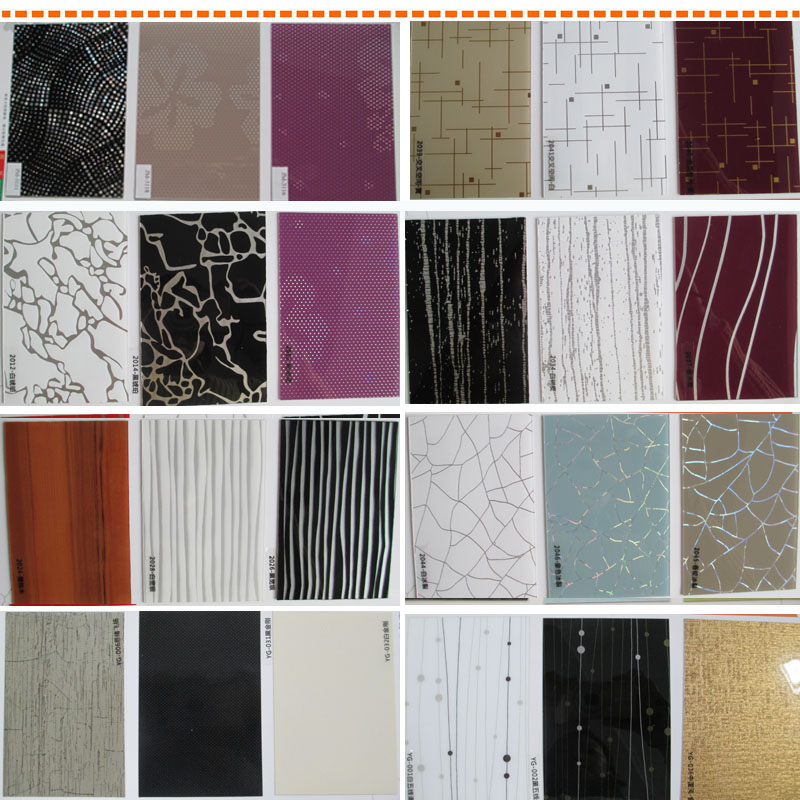

- Furniture details - represent a huge variety of colors, the most common of which are wenge, sonoma oak, ash, walnut, white and others. This palette allows you to choose a shade for future furniture. Parts are often made from laminated particleboard, which reduces the cost of the manufacturing process and the final cost. The use of furniture panels can be found in the manufacture of tables, hinged shelves, cabinet cabinets, cabinets, drawers. A large number of panel sizes allows the consumer to independently design a piece of furniture without using the services of salons;

- Plates are large-format panels that are used to decorate walls, floors, and strengthen various structures. Often, the material for the manufacture of plates is represented by two types - chipboard and MDF. The thickness of the blanks varies significantly - in laminated panels it is thicker than in versions of MDF. The plates were used as the basis for large furniture. For example, such a base will serve as a good place for fastening the side planks of a sliding wardrobe with dimensions of 2400x2400 mm. With such large formats, the cabinet design must be supported by additional details, the plates are suitable just for this;

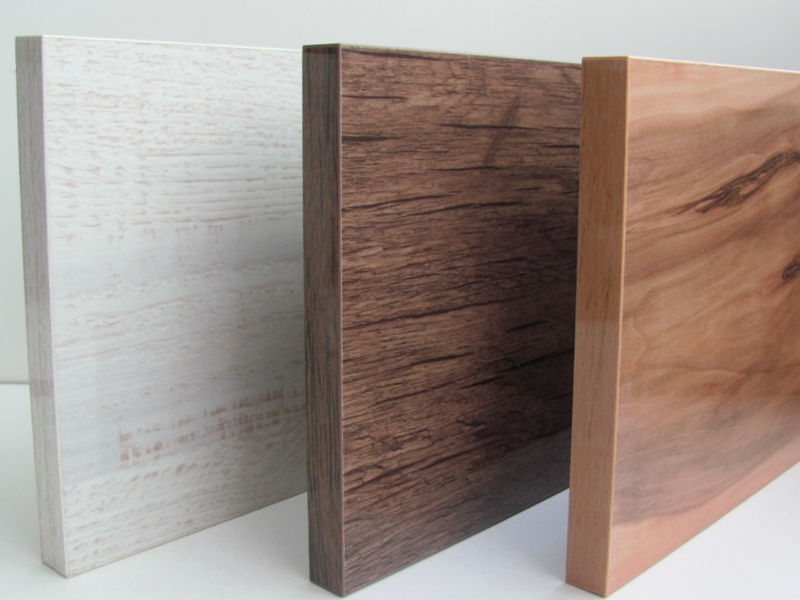

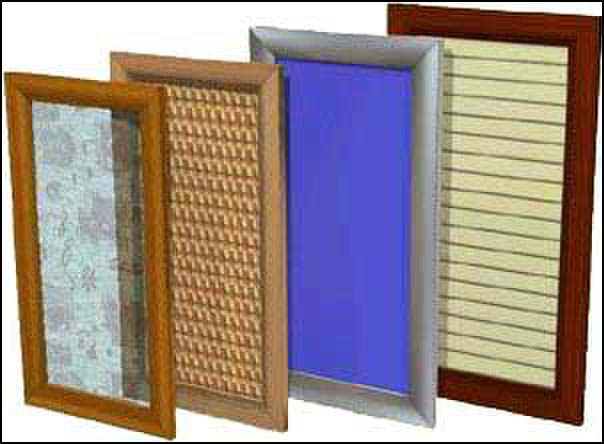

- Facade furniture panels - are considered one of the common varieties of products that are used to decorate the appearance of furniture. Doors for curbstones, swing cabinets, sideboards are made from these details. Some options are equipped with carved windows, where windows are subsequently inserted. Facades are made of natural wood or veneer. They go on sale unprocessed, but polished, which gives the consumer the opportunity to independently choose a color.The panels glued with a decorative film are very popular. They can be of any color, in addition, often decorated with photo printing;

- Shields - represent a separate category that relates to unprocessed blanks for furniture. These are rectangular or figured products prepared for further decoration in furniture design. Shields are made of larch, pine, ash, walnut.

The low cost of furniture panels makes them widely popular. In addition, if it is necessary to repair shelves in the finished purchased product over time, you can always find a suitable color on sale and replace the part yourself.

Parameters and dimensions of panels

The main difference between parts and furniture panels is their size. If parts are presented on the market in small formats, then the dimensions of the panels can reach huge levels. To understand what is at stake, it is recommended to consider the parameters and sizes offered today:

- Thickness - as already mentioned, this indicator of the product may vary. The initial thickness does not exceed the thickness of the parts used for the manufacture of furniture. It is 16 mm. The following are options for 20 mm, after which there are panels of 26 and 40 mm. It is worth noting immediately that the weight of the latter option can reach 700 kg per 1 cubic meter;

- Length - the highest indicator noted in building materials stores - length 2700 mm. Such a blank is ideal as a base for a sliding wardrobe or a swing type model. An important point is the fact that manufacturers offer panels that are completely ready for use. The user does not need to additionally glue the edge of the part. Other common lengths are 600, 800, 1200, 1500, and 2000 mm. The listed range is conveniently used for assembling complex structures, for example, an integrated cabinet with a large number of shelves;

- Width - panels for furniture are available in widths of 200, 300, 500 or 600 mm, which determines the subsequent depth of the finished item. Such a choice is not accidental, because the entire size range involves standard formats for shelves, planks and other details;

- Production material - it was noted above that production is carried out from laminated chipboards, as well as MDF material. If the first option has an affordable cost, then MDF has a more decorative function. It is customary to make such panels not only furniture, but walls. They are polished or laminated on both sides. In this case, chipboard is produced in only one variety, but has a rich color scheme. It should be noted that decorative panels have a higher cost than conventional parts;

- Weight - this indicator is calculated based on length, thickness and width. For example, a panel measuring 2700x600x16 mm made of chipboard will have a weight of 16.5 kg. With such a bulky part, you can easily assemble a bookcase, cabinet or furniture wall. A variant of MDF, with a width of 300 mm, a height of 2700 mm and a thickness of 6 mm, designed for external decor of surfaces, will weigh 3 kg. These indicators should be taken into account when calculating the load on the future product;

- Country of origin - most stores today offer domestic panels. This parameter can be explained: huge factories independently cut on the spot, and then deliver the products to retail stores. If we consider options for foreign production, some panels will be better, but the price of them will differ significantly from local offers;

- Warranty periods - the average warranty period from the manufacturer is from 2 years to 36 months. If during this period of operation the panel has dried up, cracked or changed its technical characteristics, you can contact the manufacturer.

If for the manufacture of home furniture requires an informal furniture panel, it does not make sense to look for it in stores. In this case, you must contact the large wood cutting workshops or warehouses.

Areas of use

The scope of furniture panels is wide, it is supplemented every day. To find out in what form and where they are used, it is recommended to familiarize yourself with the information:

- Kitchen sets - which can be better and more practical than self-made kitchen items. When a person knows exactly what furniture he wants to get, panels will come to the rescue. It is enough to draw up a project, and draw the size of each part. With the finished project, you should go to the workshop, where experts sawed chipboard - laminated panels. All that remains to be done is to assemble a kitchen set at home slowly;

- Halls - large volumes of this furniture do not allow the use of ordinary parts for its manufacture, and the panels do an excellent job. From the wide panel, you can make the back wall of the hallway, side racks, upper and lower shelves. If you use a panel measuring 2700x800 mm, then from the remnants of the material it is realistic to make a shoe shelf of a stationary type. This approach makes panels a profitable raw material;

- Children's furniture sets - it is inconvenient to purchase children's furniture separately in a room - the color, size and design vary. The manufacture of children's furniture from solid plates helps to obtain products made in one design;

- Living room walls - a huge wall for a living room is unlikely to be assembled from furniture details, and the panel here will be appropriate. Since the carrier frame of the headset is usually located along a long wall, it will require a large amount of raw materials to be spent on it. The panel is cut according to predetermined dimensions or divided into several parts for easy transportation;

- Trading counters - billets have found their application in the field of trade: to make a long working counter, a rack for the bartender or dimensional cabinets for storing goods is possible only with the help of large furniture panels. A furniture plate will also be appropriate here - a part for large products;

- Student furniture - the widespread use of panels can be found in the production of school furniture - desks, tall and wide cabinets where teachers store the necessary attributes - all this is made from the specified raw materials;

- Public premises - in the trading rooms, toilets, sanitary and office premises, high-quality partitions are made of plates. For this, an increased material thickness is used - 40 mm;

- Window sill decoration - strong and heavy slabs are well suited for creating window sills. However, such window sills will not perform the function of conventional devices - they are used as a dining area or a place to relax;

- Application as a finish. MDF furniture panels are well suited for indoor decoration work. Their thickness is 14-16 mm, so the workpiece can be used for wall decoration, surface lining.

The panels are characterized by a uniform structure, as well as ease of processing. With them, it is convenient to design furniture yourself, and a large number of colors allows you to always find the right option for replacing worn parts.

Which is better to choose

Choosing furniture panels, you must first determine their purpose. Stable, massive structures will require reinforced slabs with greater thickness. For finishing work, thin plate options are suitable. Information on the two types of materials used in the manufacture of panels can be found in the table.

| Chipboard | MDF | |

| What is more suitable for | Laminated panels are well suited for the manufacture of cabinet furniture for various purposes: office, student, medical, home. | Finely dispersed plates are topically applied for facing products. The facades of this material come out durable and stylish, they are easy to milling, so they are so widely used for decorating kitchen sets. |

| How is the production | For the manufacture of the plate, high-quality chipboards are used, which are previously polished. After that, using high temperature, the machine glues the surface of the panel with a paper-resin film. It gives completeness to the workpiece. | The material is obtained by working out a wooden massif, therefore, it is much stronger than other types of raw materials. The material is dried in ovens, as a result of which a lignin component is released, which sticks together wood particles. |

| What are the types | Veneered - natural veneer is used for the surface material. Laminated boards - pasted over with a melanin film. Painted panels - do not imitate wood, look plain. |

From this information, we can conclude: the use of furniture panels becomes profitable in the production of large-sized furniture sets. Having chosen the necessary color, you can neatly fit the product into the existing room interior, thereby preserving the overall design of the room.

A photo

Video