Properties of quality foam rubber for a sofa, its variety and brand

The modern furniture industry uses many types of raw materials of both natural and artificial origin as a filler for sofas. But most often polyurethane foam is used, which is known to a wide range of consumers more as foam rubber. This material has been popular since time immemorial; over the years of its existence, it has undergone significant changes and has been maximally improved. Sometimes manufacturers combine foam rubber for a sofa with other analogues - sintepon, latex, felt, but more often they use combinations of one filler of different degrees of density. What are the advantages and disadvantages of PPU, how they affect the functional characteristics of furniture, it is worthwhile to understand each user who is in search of an ideal sofa.

Features of quality material

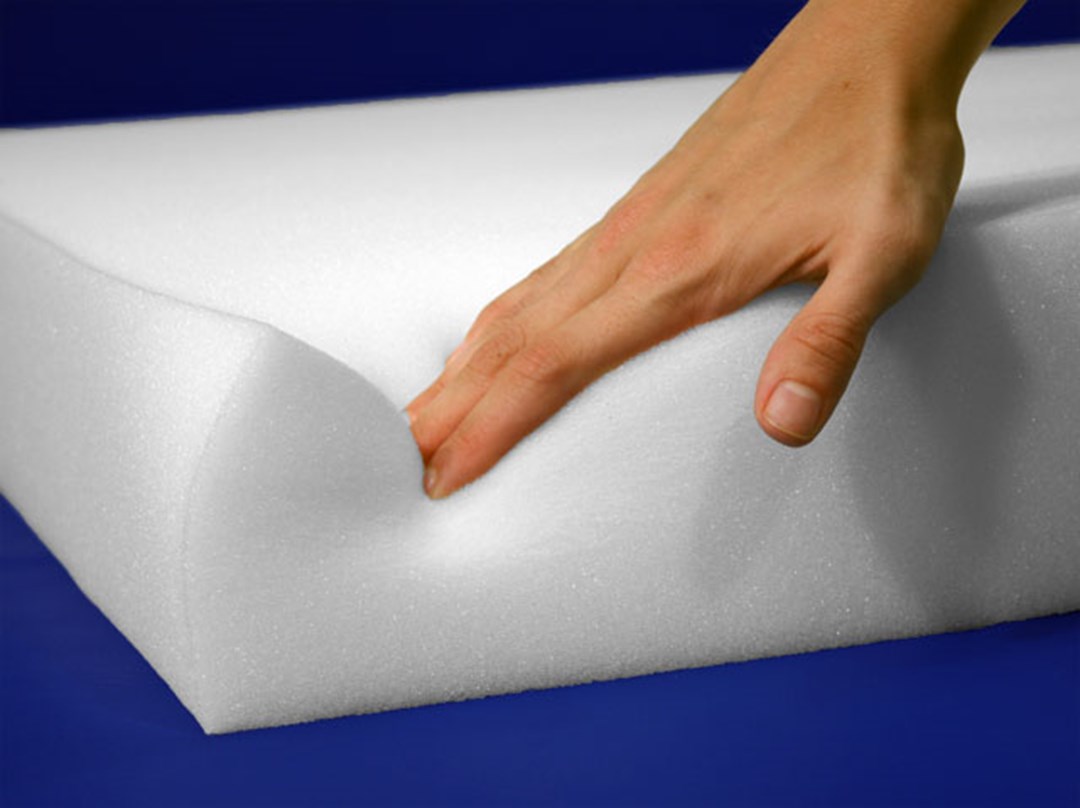

In order that over time the upholstered furniture does not lose its original properties, when buying, attention should be paid to the characteristics of the filler. In the first place is the density of foam rubber for stuffing the sofa, it should have an indicator of 22 kg / m3. In this case, the life of the sofa will be long, the furniture will be able to withstand increased loads. The second important indicator of quality is the thickness of the foam rubber for stuffing the sofa, it should be at least 4 cm.

Manufacturers who neglect the standards have low quality furniture, so its service life is significantly reduced.

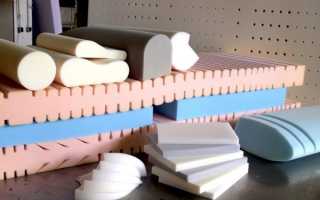

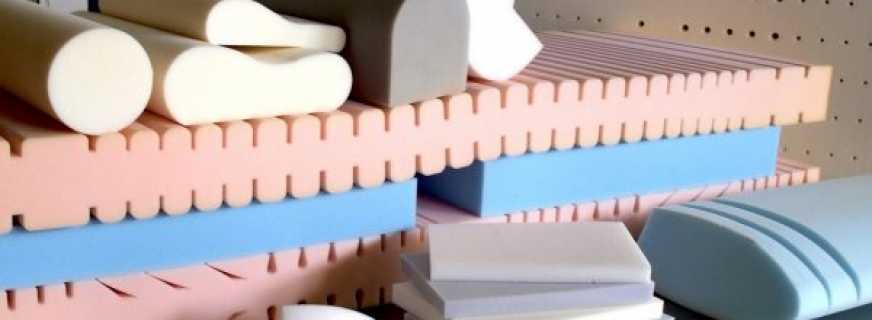

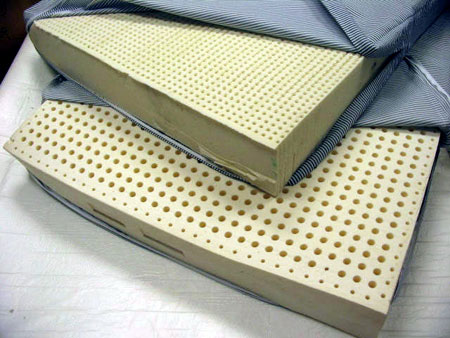

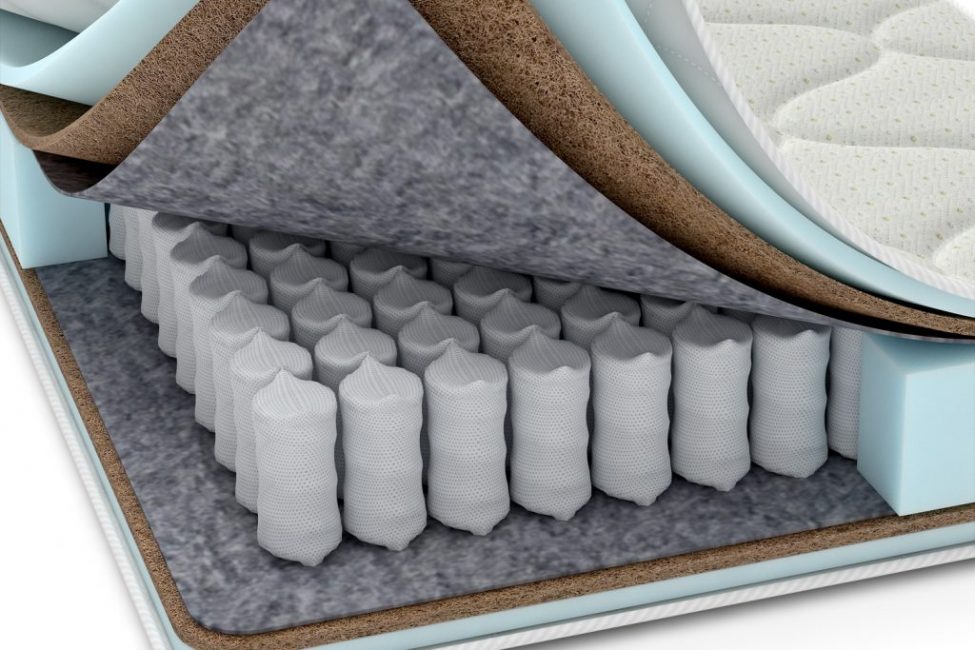

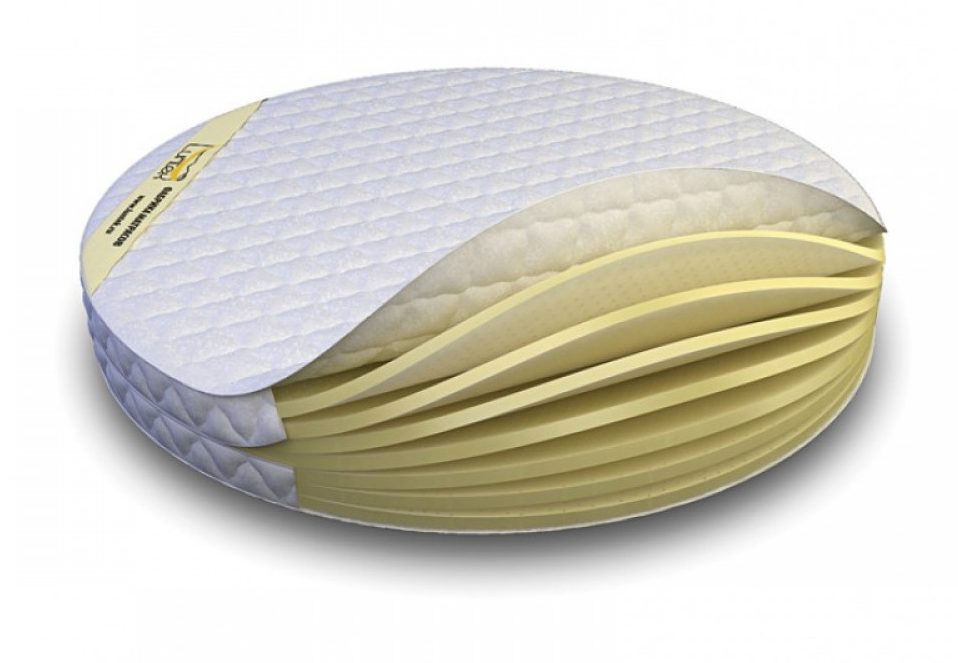

Highly elastic foam filler produces expensive upholstered furniture. This type of polyurethane foam has a multi-stage structure of “puff cake”. In the classic version, it consists of a thin upper sheet of low density and a lower layer, which is more elastic. The upper deck has a high rate of comfort, and the bottom provides reliable support. Despite the fact that such material is expensive, it is in demand in furniture production, as it guarantees high quality products.

Meanwhile, the convenience of a berth does not always depend on its density or softness. The best orthopedic effect is achieved when the foam sheets are moderately elastic and elastic. Therefore, acquiring upholstered furniture, you should pay attention to the indicator of comfort. There is a tendency to supplant standard grades of high rigidity with analogues that differ in improved characteristics. Orthopedic properties have foam rubber for a sofa in the living room with a density of at least 30 kg / m3. For the back, the filler is mainly used 25-30 kg / m3. This density has a load limit of 60-80 kg. For higher indicators there are no restrictions on the created pressure.

For enhanced comfort, the material is combined with soft and ultra-soft HS sheets.

Varieties

Foam sheet and rolled differ in softness and rigidity.Products are:

- Soft - this type of filler can be used in furniture only in conjunction with a dense foam base. This is the most plastic polyurethane foam (PUF), which gives increased comfort to finished products. But it should be remembered that with the independent use of the material, the created load cannot exceed 60 kg.

- Solid - hard, able to withstand heavy loads of up to 100 kg.

- High hardness - highly rigid polyurethane foam can withstand a mass of more than 100 kg.

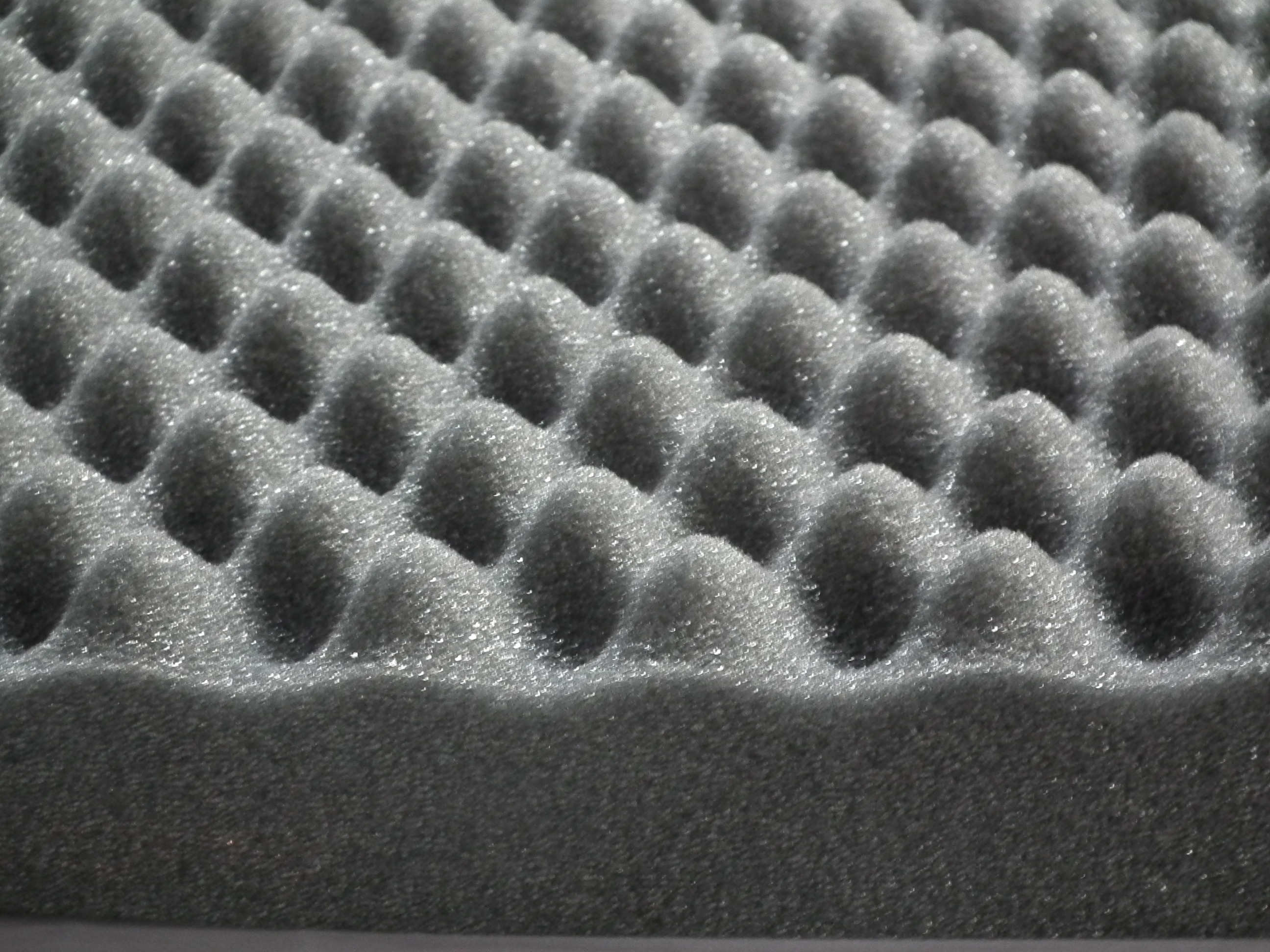

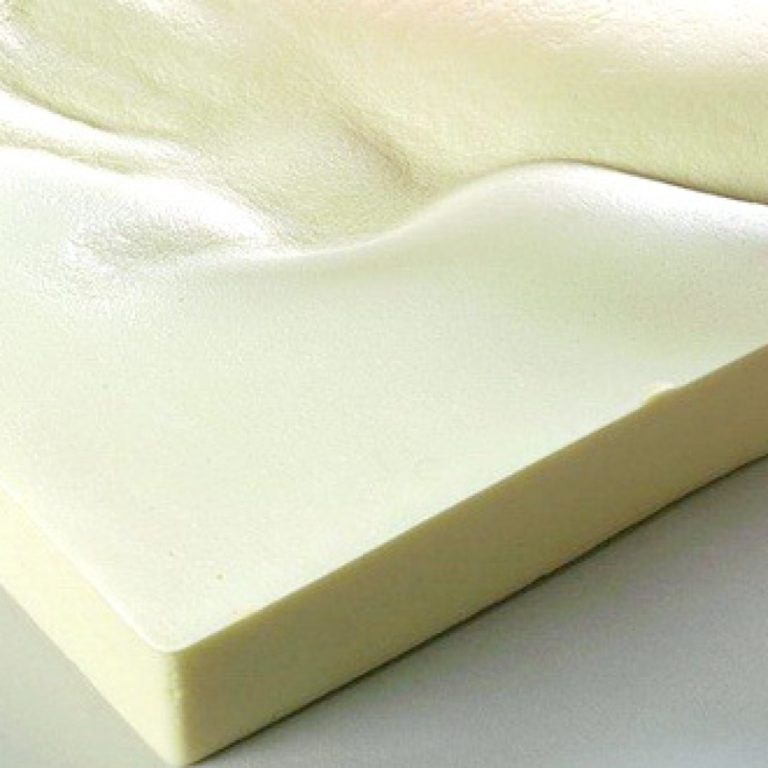

- Elastic comfort - foam rubber is best suited for upholstered furniture designed for sleep. On such a surface you can relax most comfortably.

- Elastic with orthopedic effect - products are characterized by healing properties, as they reduce the load on all parts of the body.

Foam rubber with orthopedic effect "adjusts" for each person individually, the main thing is to choose the material for the consumer weight category.

Furniture Foam Stamps

Modern production uses the following PPU brands:

- ST - standard raw materials, contains a polymer such as polyol (polyesters). The rigidity of the products is achieved by selecting the ratio of the components of the basic composition. The result is sheets that differ in characteristics. Basically, at least 2 types of polyol are used.

- EL - increased rigidity.

- HL - hard, composed of different types of polyol.

- HS - soft and super soft. Special polyester is used in production instead of ST or in addition to it.

- HR - high elasticity. The composition contains only polyols in 2 or 3 combinations.

- Special - not subject to burning, are viscoelastic.

The first grade formulation contains special melamine powder, Bayer PHD polyols, flame retardants in the form of additives. Melamine provides fire resistance, at the same time it negatively affects the properties of furniture foam. Viscoelastic grades contain polyesters and isocyanates.

The most common brands of furniture filler are:

- HS2520 - monolithic amplifier is used on the back of the sofa with a load of 80 kg;

- HS3030 - maximum weight 100 kg;

- HS3530 is the best foam rubber for upholstered furniture, backs with a load of 100 kg, seats - 80 kg are made of it.

Foam is labeled according to 3 indicators: type, density and stiffness. For example, the EL2540 brand is a hard sheet with a density of 25 kg / m3 and a stiffness of up to 3.2 kPa.

Criterias of choice

Choosing high-quality sofa foam, It is important to pay attention to the following parameters:

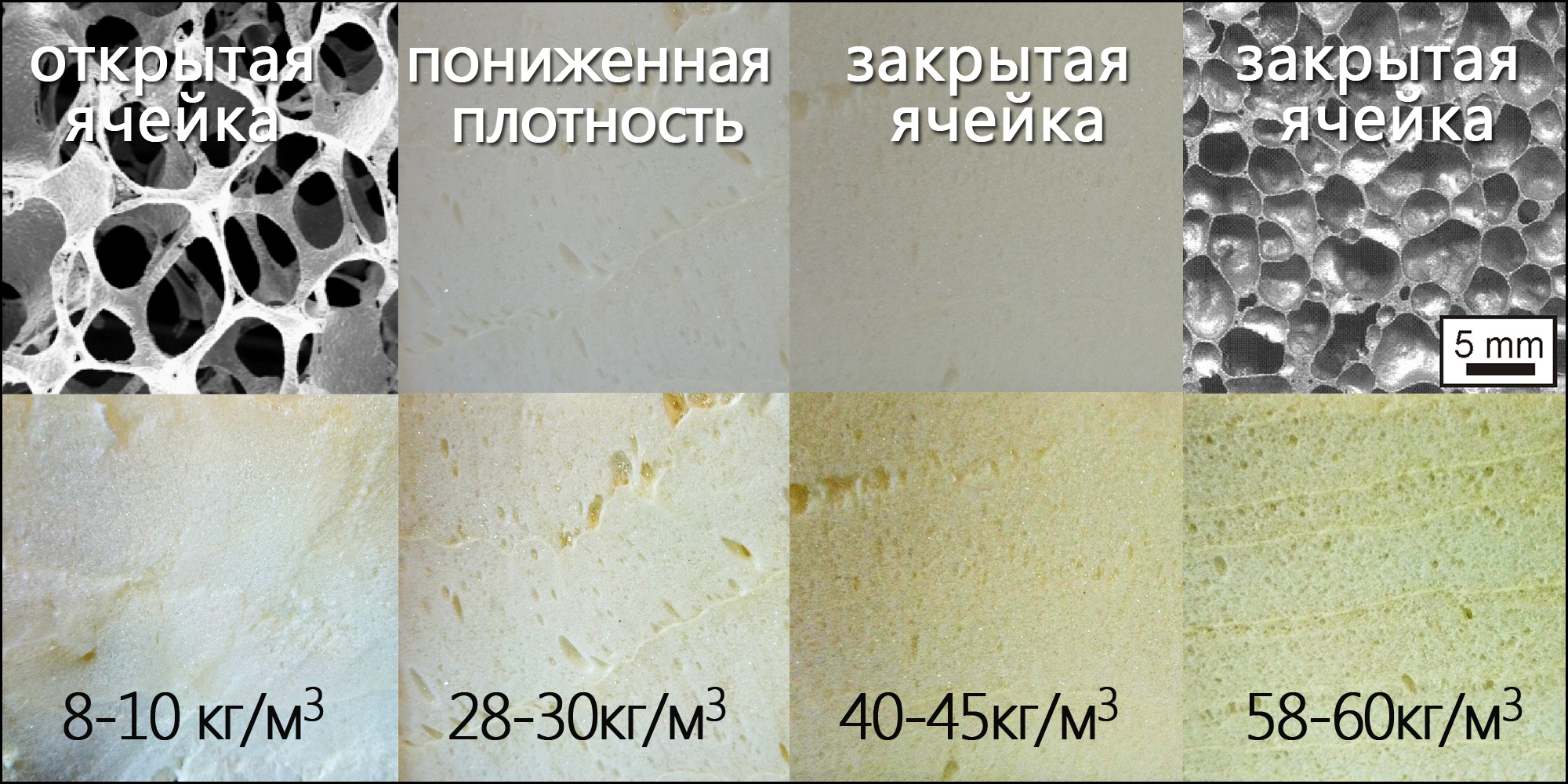

- Density. It directly affects the duration of the operational period. The indicator received another name - “apparent density”, since the cellular structure of the sheet provides for the presence of air masses. Among other things, the density of furniture foam has a direct effect on the compression stress. For example, if it will be 25 kg / m3, then this indicator should be equal to 4 kPa.

- Elasticity, which affects the possibility of a comfortable location on the surface of the sofa. The parameter is determined using a special ball falling freely from a height. The farther it bounces off the foam pad sample, the less elastic the base has.

- Compression stress - the value indicates the level of rigidity of the foam sheets. According to ISO 3386 DIN 5377, this indicator helps to determine the force (kPa) applied to compress sheet by 40%.

- Residual deformation (distortion) - indicates the ability of the material to remain in its original parameters and shape throughout the entire operational period. The main requirement for furniture foam is that it should have a low distortion index.

- The strength provides tensile strength and gives a low elongation.

- The comfort factor determines how pleasant the touch is on the surface.

- The support coefficient indicates the ability of the filler to retain its shape and distribute the generated loads.

The foam density indicator can vary regardless of the manufacturer. For example, when the sheets have been strongly twisted for a long time during transportation, the compression stress decreases to 3.4-3.5 kPa.

Replacing foam in the sofa is a rather expensive service, so it’s better to initially overpay for high-quality and durable furniture, because, as you know, you can’t save on comfort.

Video

(votes: 1, average rating: 4,00 out of 5)

(votes: 1, average rating: 4,00 out of 5)