Varieties of transformer benches, design features

When you make a personal plot you can not do without convenient benches. They are an important element in the design of the territory, they allow you to enjoy the beauties of nature and relaxation. The transformer bench, which is laid out if necessary, is very popular. Due to the variety of ready-made drawings, master classes, schemes, you can make a design yourself.

Content

Product Features and Benefits

Transformer benches are simple but functional designs. The main difference from ordinary country furniture is the presence of special mechanisms. When folded, it is a simple bench, when unfolded - a roomy table with a pair of comfortable benches. The products are characterized by mobility, therefore they are suitable for installation in any corner of the site. Folding bench models have several advantages:

- Compact - a folded bench takes up very little space.

- Multifunctionality - additional seats and a table appear due to simple manipulations.

- Durability - benches made of correctly selected material are distinguished by a long service life.

- A simple mechanism - even a child can cope with it.

- Versatility - suitable for use in the country, country estate, in the garden. Benches play a decorative role in landscape design and are comfortable furniture for family gatherings.

The folding model has an attractive appearance. She looks noble even without the use of decor. In addition, the bench is quite simple to make yourself.

Varieties and interesting design options

To choose a suitable transformer bench, it is necessary to take into account the number of people who will be located on it. The number of seats depends on the type of structure:

- Bench table with benches. This variety is the most common. With the help of simple manipulations, the model is transformed from one bench into two with a table. Advantages: holds up to 6 people, does not clutter up space. The disadvantage of the bench is that it does not look very attractive when folded.

- Designer bench. When disassembled, it provides seating for up to 6 people, in the combined team - two; complemented by countertops. Advantages: usability, functionality. The disadvantage of the bench is more modest possibilities compared to the previous version.

- Bench flower. It looks like a designer, but there are also differences - when assembled, it has the shape of a bud. Advantages: adjustment of the backrest, accommodates up to 5 people.The disadvantage is recesses and cells in the seats.

There are other options for a transformer. The model with two benches is simple in design and manufacture. A corner product can include a different number of turns, provides a large number of seats. The option in the form of a coffee table has an original design, suitable for relaxing, reading, working on a laptop. The hexagonal bench table attracts attention, holds up to 8 people.

Lovers of custom solutions will appreciate the model of two chairs, which transforms into a regular bench, a bench for placing a pair opposite each other, as well as a product with a side table.

Materials of manufacture

To make a transformer table with your own hands, you need to pay special attention to the material on which the quality and durability of the structure depends. In most cases, wizards use:

- Wooden boards and timber. Ideal for making models of benches in a classic style. Wood is easy to process, allowing you to give the product any configuration. It usually takes two people to work, as the material is quite heavy.

- Pallets. Suitable for creating country style benches or Provence. It is recommended to use raw materials of foreign production, which does not have toxicity marks, does not emit unpleasant odors. The material must be carefully sanded, treated with protective impregnations, applied to the surface of the paintwork.

- Metal. Welded benches with forged elements will be an excellent option for a summer residence. Designs are made from a rectangular, round or square profile. Thick wall material is used for resistance to stress.

To create a cheap bench and table with your own hands, you can use improvised materials. Old chairs, doors, furniture panels, unnecessary nightstands - it all depends on the imagination of the master.

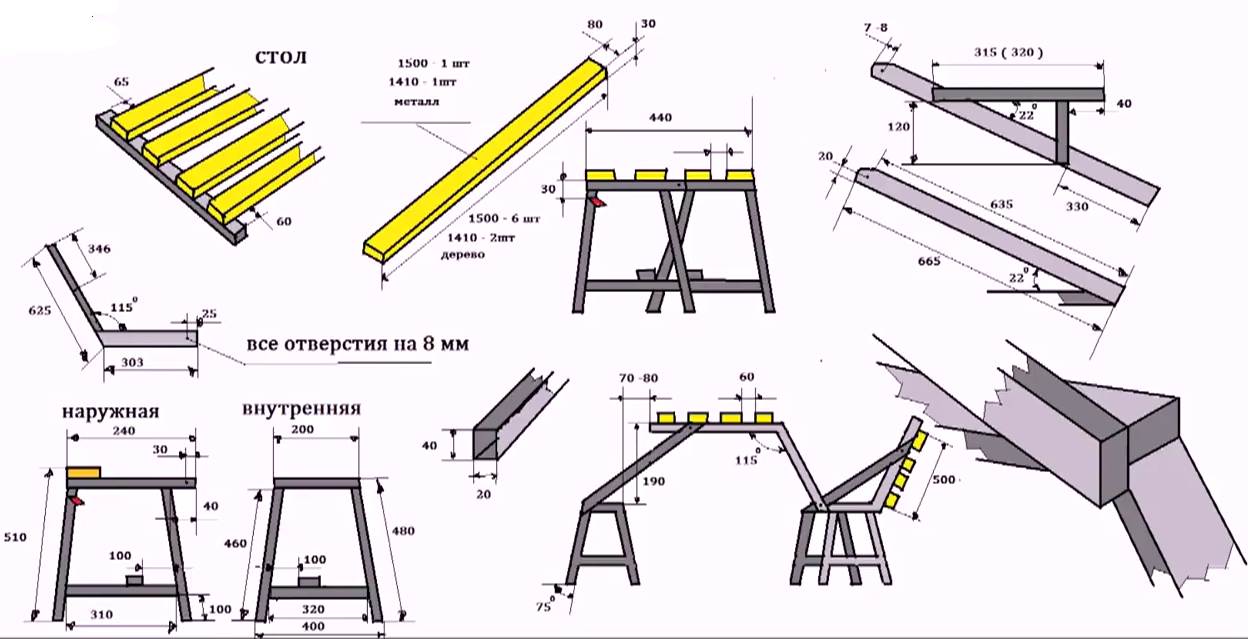

Assembly diagrams and dimensional drawings

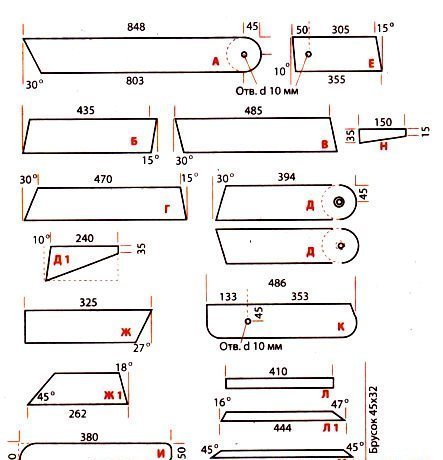

When creating high-quality transformer benches with your own hands, drawings are of great importance. The network has many ready-made schemes, but if necessary, you can draw up an individual plan. To do this, keep in mind the following information:

- First of all, it is necessary to think over a design option taking into account the number of seats, the types of bench transformation;

- the parameters of the shop should fully correspond to the area of the site where it will subsequently be located;

- on the drawing each detail of the product and the dimensions of the bench are marked;

- the dimensions of the movable elements of the bench are determined.

A typical bench layout displays the entire process of work, right up to the order in which an action is performed, so it will be an excellent assistant for beginners. To calculate the required amount of material, its length and cross-section are taken into account. So, if the thickness of the beam is 8 cm, then at least 5 units will be required to create one leg.

If the bench seat is made of a board 4 cm thick and 9 cm wide, 5 boards 150 cm long will be required for work.

How to do it yourself

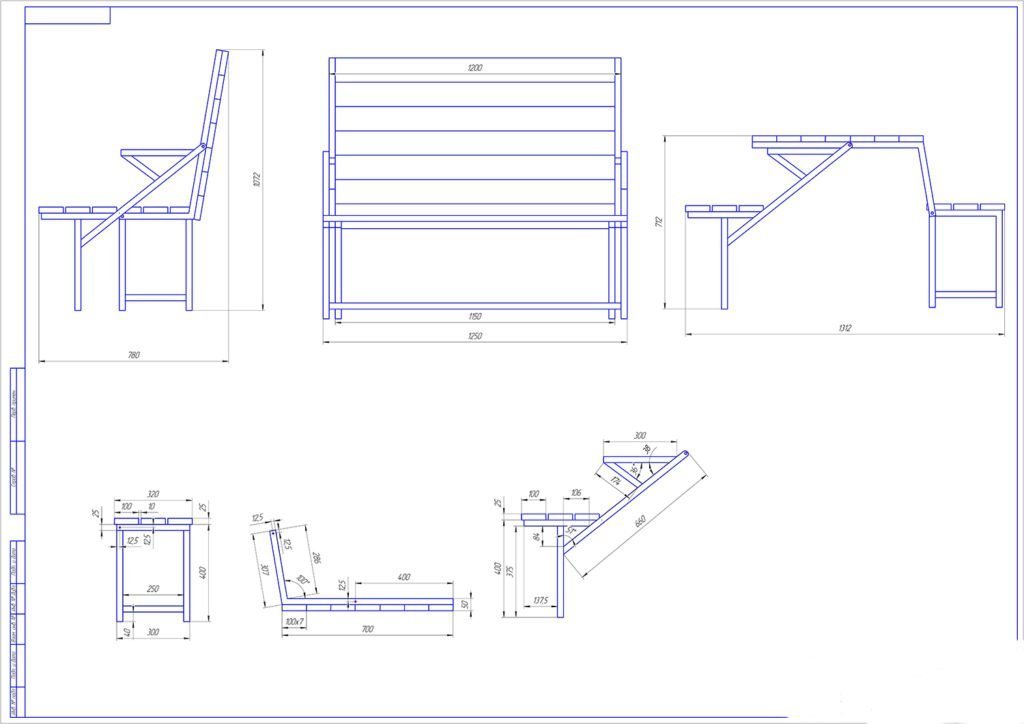

To understand how to make a transformer bench yourself, you need to use master classes. A detailed description includes drawings with dimensions and photographs of each step. The easiest way to make your own model of benches made of wood and metal.

Standard wood construction

For work, the following materials and tools will be required:

- boards and bars;

- construction level, tape measure;

- screws;

- self-tapping screws;

- marker or pencil;

- sandpaper;

- metal fasteners;

- Bulgarian;

- screwdriver;

- drill.

To make a high-quality bench table, it is necessary to carry out all the actions according to the instructions:

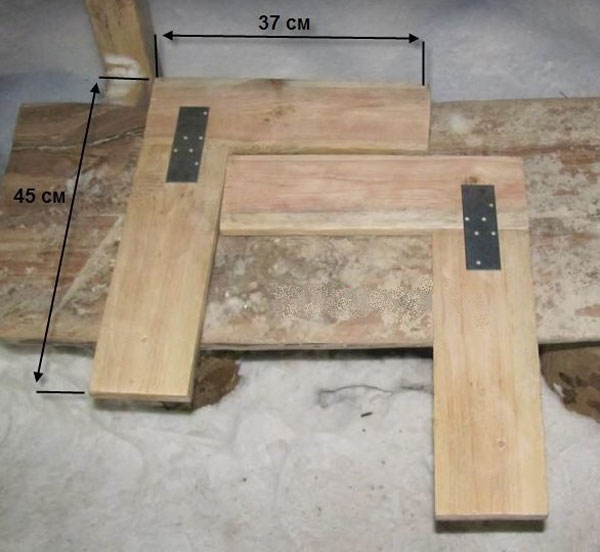

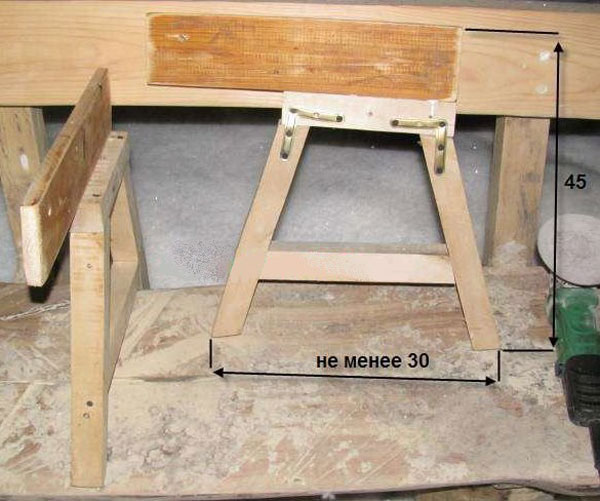

- Two boards 120 x 12 cm for the seat are carefully sanded.Two more - 37 x 10 cm (for legs) are connected to metal fasteners so that they acquire a triangular shape.

- A pair of prepared boards are screwed to the legs with screws. Holes are drilled in advance.

- The lower part of the seats is reinforced with spacers, which are fixed with corners and screws.

- For the second bench, boards with parameters of 110 x 22 cm are needed. The legs are made of timber, joined with self-tapping screws.

- The boards are screwed to the base, the seat is fixed, then the spacers. The correct assembly of the structure is checked.

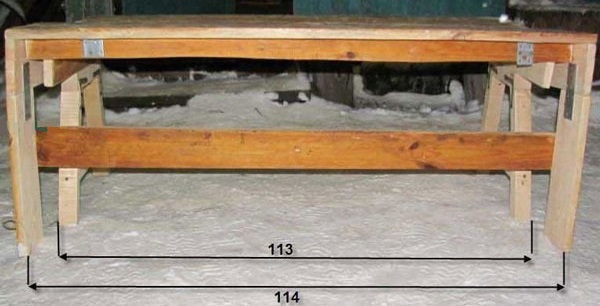

- For the countertop, 5 boards and 2 slats are taken. All elements are connected to each other. The countertop is fixed to the base.

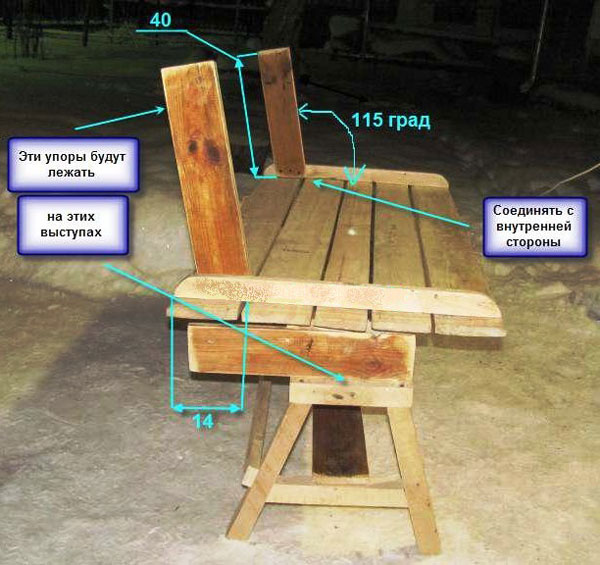

- A lever is installed that is responsible for the transformation of the model. This will require two boards of any width 88 cm long. Their ends are rounded off.

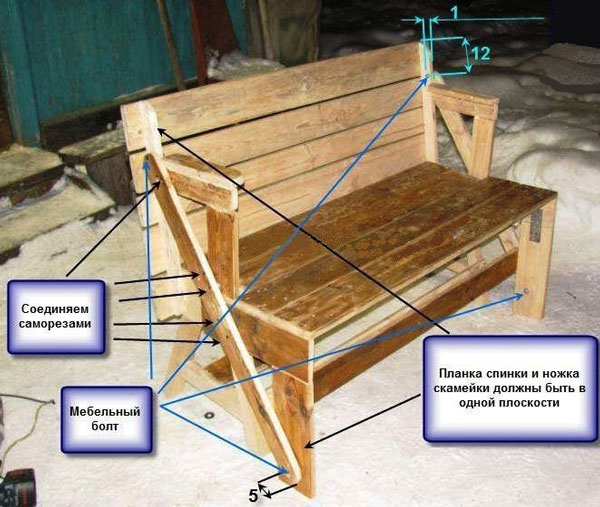

- Holes with a diameter of 7 mm are drilled in the lever, leg and bar. All elements of the transformer bench are connected using furniture screws and nuts.

To tighten the mechanism, it is necessary to fasten it to the armrest. After that, you can proceed to verify the functionality of the finished product.

The accuracy of the construction of a table with benches is determined by checking compliance with the drawing. The internal width of the structure should be 115 cm, the external - 120 cm. If these parameters are violated, the product will not fold.

Metal convertible garden furniture

Creating a do-it-yourself transformer bench is a fascinating task. To work, you will need the following tools and materials:

- square pipes 25 x 25 x 1.5 mm, a total of six pieces;

- boards - 8 pieces;

- drill;

- Bulgarian;

- screwdriver;

- Sander;

- welding machine with a set of electrodes;

- washers, nuts, bolts;

- paint for metal.

Step-by-step instructions will help you complete each step of the job correctly:

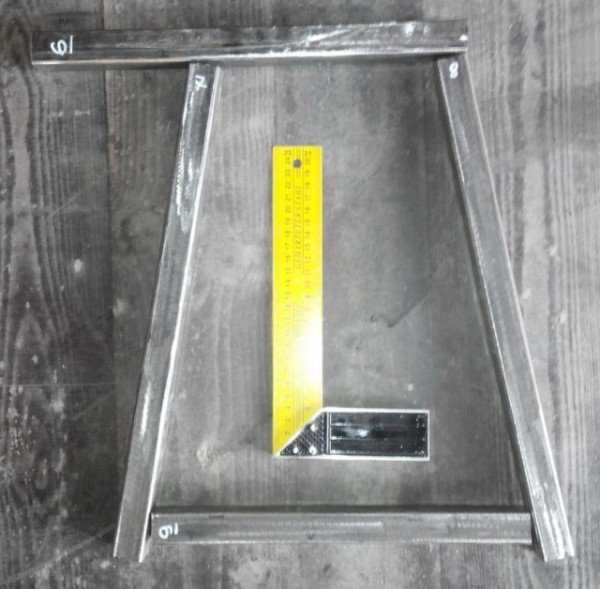

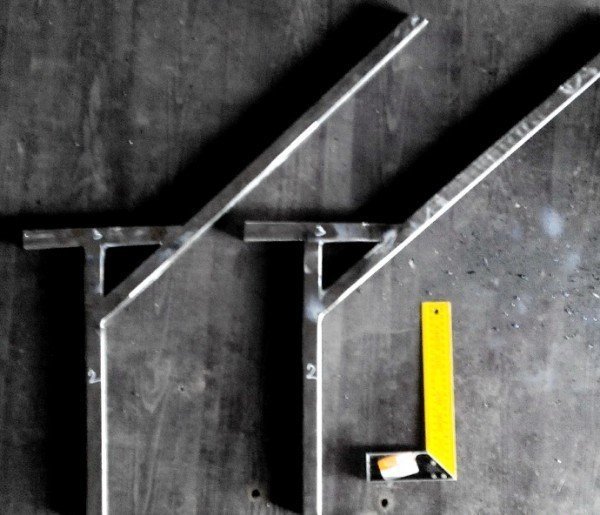

- Metal profiles are cleaned, rust is removed. Billets are cut in accordance with the plan.

- To create the frame of the bench, the tubes are welded. Drill holes for furniture bolts. Washers are used for easier folding.

- For legs from a metal sheet, elements 50 x 50 mm are cut out. All frame parts are processed with a special composition.

- The boards are cut in accordance with the parameters of the bench, sanded, impregnated with antiseptics and fixed to the body.

The metal structure can be made by experienced craftsmen and beginners, who first encountered the manufacture of garden furniture. It is advisable to have experience with welding. Otherwise, the product may not be strong enough.

Dressing

The table-bench transformer, which is located on the street, needs special treatment. For wood, stain is used, on top - varnish with water-repellent properties. But even after that it is not recommended to leave products in the open. The vagaries of the weather negatively affect its longevity and appearance, so you can transfer the design to the veranda or the gazebo, close it with a canopy.

If you create a bench with your own hands, you can decorate it in various ways. The most attractive decor on the seats and backs. To do this, use:

- images painted with colorful acrylic paints;

- decoupage drawings;

- charming pictures created by an electric burner;

- carved floral ornaments, patterns;

- figures of animals, fairy-tale characters, sawn jigsaw.

If the design was performed correctly, and the finished product is maintained regularly, the service life can reach 25 years or more. Often, wooden elements of benches are replaced with metal ones, it does not look so attractive, but durability increases significantly. A convenient and practical garden bench is always relevant in a country or suburban area. Sitting on it, you can enjoy your vacation, admire the picturesque scenery, chat with loved ones. You can make such a useful piece of furniture yourself, which allows you to realize the most interesting design ideas.