Making wicker furniture with your own hands, all the nuances

For different interiors and exteriors, wicker furniture is considered an excellent solution. It has many advantages and is presented in numerous forms; wicker furniture is created with your own hands quickly and easily, and at the same time it can fully meet the needs of direct users. The whole process is divided into simple sequential steps, so if you pre-draw a drawing, watch a training video and follow the instructions exactly, you will get a reliable and durable design.

Content

Advantages and disadvantages

The advantages of creating wicker furniture include:

- low costs for obtaining unique designs that are original;

- ecological cleanliness due to the fact that wicker furniture is made exclusively from safe and natural materials that do not cause any harm to people or the environment;

- lightness of the resulting products, so they are effortlessly transferred from one place to another;

- the technology for making wicker furniture is not considered too complicated if you carefully understand it, so this process is available to everyone;

- designs do not have any unpleasant or specific odor;

- they are easy to care for, and this does not require the use of unusual care products, but it is not allowed to leave them outdoors for a long time, as they will lose their attractiveness and high parameters under the influence of ultraviolet or rain;

- since it is planned to make wicker furniture with their own hands, unique designs that cannot be found in stores can be obtained;

- a long service life of structures makes it possible not to think about buying new furniture for many years.

In order to learn how to competently weave different designs, it is recommended to pre-train, for which different products can be created for dolls or other toys.

The disadvantages of wicker furniture with their own hands include the fact that it does not withstand the effects of various atmospheric factors for a long time, so it is not allowed to leave it on the street for a long time. Also, regular operation leads to the fact that some elements of such products will begin to weave, and repair is a complex process.

Materials suitable for weaving

Wicker furniture can be made using various materials. The main requirement for them is high flexibility and durability. The most commonly used materials are:

- banana leaves - they have a length of up to 350 cm and high strength.This material is considered suitable not only for creating different unique and unusual furniture, but also for obtaining a variety of ropes or ropes. It has a small mass, and furniture made of material has a dark brown color;

- Bamboo - it is considered quite tough, so beginners are rarely used. It is difficult to obtain any specific products from this material. Usually used bamboo chips, effectively used to obtain unique decorative elements;

- rattan - any wicker product made of this material is distinguished by sophistication. It is considered easy to use, inexpensive and giving the opportunity to get original furniture. The production of various designs is considered so simple that it is available to everyone. The products obtained are durable as well as resistant to moisture;

- willow - weaving furniture from willow is a popular procedure, as this material is chosen most often. It has good durability and excellent flexibility. The disadvantages of willow construction include a tendency to crack, which significantly spoils its appearance, and it is almost impossible to fix this drawback. Also, the rods are considered quite rigid, so often there are difficulties when they are bent;

- paper - it is not used to create any interior or exterior items, but weaving from newspaper tubes or plain paper is considered popular. It allows you to make furniture for dolls or various decorative elements that fit perfectly into a variety of interior styles.

Having understood what furniture is woven from, you can begin the direct process of weaving.

Necessary tools

How to make wicker furniture? This process is not considered too complicated, but you must first prepare for it so that all the tools and materials are at hand. To do this, by all means must be available:

- hammer and screws;

- high-quality glue intended for fixing various materials;

- direct material for weaving, which can be represented by different rods.

For beginners, it is recommended to use rattan, since this material is considered the easiest to use, but if you want to get wicker furniture from the willow with your own hands, you need to prepare for a rather complicated process, since the rods are very rigid.

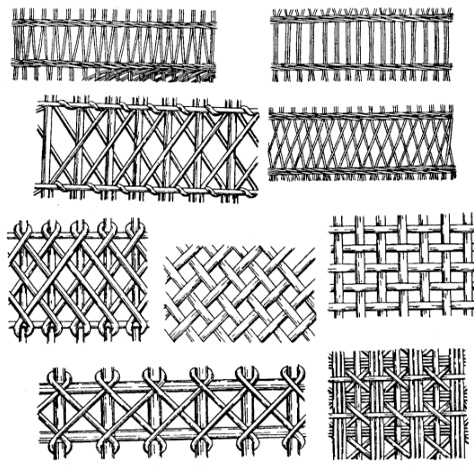

In addition to the preparation of materials, it is necessary to determine what kind of weaving will be used:

- single, in which you need to work with only one rod;

- combined, using several rods at once, but such a technique is considered quite complicated, therefore it is suitable only for experienced craftsmen;

- openwork, allowing you to get really unique and unique in appearance designs, however, such work will have to spend a lot of time, and it is also considered quite complicated.

It is necessary to provide in advance a strong fastening of all the components of one furniture, otherwise it will not last too long. Connections of individual elements may be detachable or one-piece. In the first case, any design can be disassembled if necessary, and then reassembled, but this method is not used too often. The technique of one-piece connection, which ensures the strength of the resulting structure, is considered the most optimal.

Sofa manufacturing technology

The master class of this process for beginners is presented step by step below. The procedure does not have any specific difficulties, so it can be performed even by people who do not have complex skills.

Pre-performed actions:

- the material used for work is selected, and most often an artificial or natural rattan is bought for this, since these elements have an affordable cost and are easy to use;

- it is important to check that the purchased rods do not have any defects, and if natural materials are bought, it is advisable to sand them to ensure that smooth surfaces are obtained;

- it is determined what sizes and other parameters the future sofa will have;

- it is advisable to make a special scheme of the future design, according to which all work will be performed;

- the method of weaving is determined, and since a novice acts as a master, the standard single weaving that does not require experience or special skills will be optimal for him.

After completing all the preparatory steps, you can begin the direct process of creating a sofa.

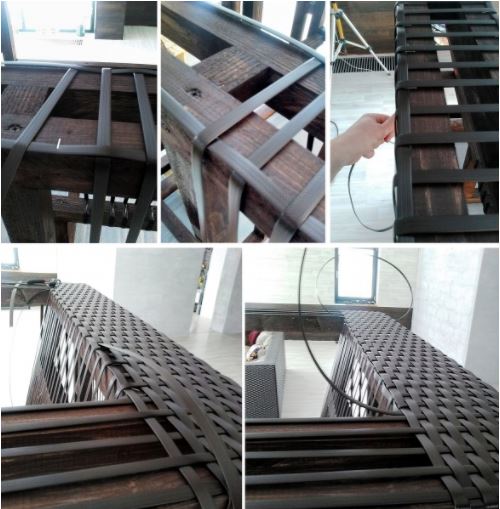

Seat frame

The frame is initially made. Some wicker furniture can be made without it, but not a sofa, since quite significant loads will certainly affect it during operation.

The frame can be made of wood or metal. He must completely repeat the shape and size of the future seat. It is important to use materials coated with special protective agents that prevent the process of corrosion or decay. Self-tapping screws or other fasteners can be used to connect the individual parts. The resulting frame is braided with selected rods, for which you can use different weaving technologies.

Legs and back

Three or four legs can be selected. Their height can also be different, and for this, the growth and other dimensions of people who are the main users of the resulting sofa are estimated. Their optimum height is 40 cm. They are fixed to the seat with self-tapping screws, and the distance between them should be the same.

To create a back, a metal rod or wooden stick is prepared. In length, this element should be slightly larger than the seat. It is fixed to the hind legs with self-tapping screws. The resulting structure is covered with wicker elements that are connected to each other reliably and tightly.

Give rigidity

A sofa made of wicker elements must be reliable, for which, during its manufacture, it is imperative to give it rigidity. To do this, the following actions are performed:

- between the side legs the same wooden sticks are attached with self-tapping screws;

- they should be at the same height;

- two sticks are also used to connect the hind legs, and they are fixed diagonally;

- the rod of the selected material is folded into an arc, after which it is fixed to the left side of the back, and its ends are attached to two legs, and the upper arc is connected to the back;

- the same work is done on the other side of the back;

- one more large-sized rod is taken, which also folds into an arc;

- its ends are fixed to the front legs with small nails, and the upper part is attached to the seat.

Assembly assembly

At the end of the work, the structure is assembled. For this, all elements are reliably and firmly connected to each other using suitable fasteners.

If the fasteners are not too reliable, then it is allowed to strengthen them with a high-quality adhesive solution. The design made is processed with special protective compounds, after which you can proceed to decorate it.

Dressing

Various methods can be used to decorate such furniture:

- coating with various protective varnishes or paints;

- creating a soft spot with optimal upholstery, featuring an attractive appearance;

- attachment of additional elements of glass, metal or other materials.

Thus, creating your own wicker furniture is quite simple. For this, various unique ideas and desires of the owners of the territory can be embodied.A small amount of money is spent on the process.

Video